STARTING LARGE SYNCHRONOUS MOTORS

The earlier part of this unit described how a synchronous motor is started. In general, the starting current for synchronous motors is less than that for squirrel-cage induction motors having the same horsepower and speed ratings. In most cases, it is preferred to start a synchronous motor at full voltage. Motors as powerful as 10,000 or 15,000 hp can be started at full voltage. This type of starting does not harm a motor that is properly designed. Full-voltage starting means that a simpler, less expensive starter is required as compared to reduced-voltage starting.

When the motor starting inrush causes voltage disturbances, reduced-voltage starting current can be used. Approximately 50% to 65% of the rated line voltage is applied to the motor through a reactor or an autotransformer starter.

At a reduced voltage, the motor starts as an induction motor. It then accelerates to a speed close to the synchronous speed when the autotransformer, or reactor starter, is shifted into the running position. At this point, the dc field circuit is energized.

Many automatic motor starters use special relays to energize the field circuit. The circuit must be energized at the correct instant to ensure that the maximum pullin torque is obtained with a minimum amount of disturbance to the system. After the motor is operating properly as a synchronous motor, the dc field excitation current is adjusted to give the desired power factor.

SYNCHRONOUS MOTOR RATINGS

The nameplate data of a synchronous motor contains the same information as the nameplate of an ac generator. The only exception is the output rating because the alternator is rated in kVA and the synchronous motor is rated in horsepower.

The nameplate of a synchronous motor also gives a power factor rating. This type of motor is usually rated at unity power factor, 90% lead power factor, or 80% lead power fac- tor. The motor may be rated at other power factor values for special applications. If a motor is rated at unity power factor, it can be operated with a leading power factor. In this case, the mechanical load must be decreased so that only the rated ac stator current will flow at the reduced power factor. In other words, the mechanical load, in horsepower output, and the electrical load, in leading kilovars, must not exceed the rating of the motor. When a synchronous motor is rated at a leading power factor of 80% or 90%, it will have a larger current capacity for a given horsepower output. This is necessary if the rated horsepower output is to be supplied for the larger current at the reduced power factor.

Synchronous motor losses are the same as those for an ac generator. The losses include the power spent in the separately excited field, the mechanical friction losses con- sisting of the copper losses in the three-phase stator winding and the stray power losses, the windage losses, and the iron losses. The efficiency of the three-phase synchronous motor is slightly higher than that of an induction motor having the same speed and horsepower ratings.

SMALL SINGLE-PHASE SYNCHRONOUS MOTORS

The Warren Motor

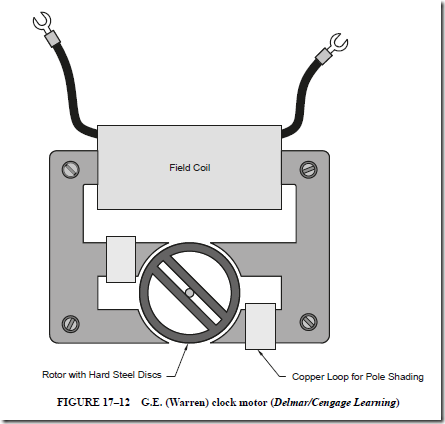

Small single-phase synchronous motors are used in many timing applications, including electric clocks, time switches, graphical recording instruments, and stroboscope devices. These motors do not require dc field excitation. A widely used motor of this type is the Warren (or General Electric) clock motor. It consists of a laminated stator core with an exciting coil. Normally, this coil is wound for 120-V operation. The coil has two poles, and each pole is divided into two sections. One turn of heavy copper wire is placed over half of each pole to produce a rotating field effect.

A General Electric (Warren) clock motor is shown in Figure 17–12. The rotor consists of several hardened steel discs that are pressed on the small rotor shaft. The discs have a high hysteresis loss. The rotating field acts on the rotor to produce strong torque. The rotor accelerates to a speed near synchronous speed. It then locks into synchronism with the rotating field. The flux of the rotating field seeks the path of minimum reluctance (resistance) through the two small rotor crossbars.

Operation with Two-Pole Stator

How is a rotating field effect obtained with the two-pole stator? As the flux increases in value, part of the flux attempts to pass through the section of the pole having the copper shading loop. This flux induces a voltage and current in the copper loop. These induced values oppose the flux that produces them. Thus, most of the flux passes through the nonshaded section of each pole. After the flux reaches its maximum value, there is no change in the flux instantaneously. Then, the induced voltage in the loop decreases to zero. The current in the copper loop also drops to zero, as well as the opposing mmf of

the short-circuited coil. A large part of the main field flux now passes through this section of the pole piece. When the main field flux begins to decrease, voltage and current are induced again in the copper loop. This time, the mmf developed attempts to prevent the flux from decreasing in the shaded portion of each pole piece. In this way, a type of rotating field is created. The flux first reaches its maximum value in the nonshaded section of each pole and later reaches its maximum value in the shaded section.

The rotor speed for the single-phase, two-pole synchronous clock motor is 3600 r/min when operated from a 60-Hz source. A gear train is housed in a sealed case containing a light lubricating oil. This train reduces the speed of the motor to the value required for use in various timing devices.

The Holtz Motor

The Holtz motor (Figure 17–13) is another type of single-phase synchronous motor. This motor has the same shaded-pole arrangement as the General Electric (Warren) motor. For the Holtz motor, however, the rotor has six slots that hold a small squirrel-cage

winding. The rotor slots are arranged so that six salient field poles are formed. The Holtz motor starts as a squirrel-cage motor. When operated from a 60-Hz service, the salient poles of the rotor lock with the sections of the field poles each half-cycle. The resulting speed is one-third of the synchronous speed, or 1200 r/min.

SELSYN MOTORS

Selsyn is a contraction of the term self-synchronous. Selsyn motors provide a means of electrically interconnecting two or more remote points of a system. This means that they give automatic synchronized control or indication at one point, with respect to the other point. Selsyn units are extremely flexible and are used widely in industry.

For example, selsyn motors are used to give indications of the positions of remote devices such as generator rheostats, steam turbine governors, waterwheel governors, trans- former tap connections, swing bridges, gates or valves, elevators, and the roll height in steel rolling mills. They are also used in many automatic control systems, signaling systems, and remote control systems.

Figure 17–14 shows the internal wiring of a selsyn motor. The rotor terminals are marked R1 and R2. The terminals marked S1, S2, and S3 are the stator terminals. The rotor field circuit is excited from an external single-phase source. The stator windings consist of a conventional three-phase winding.

Two selsyn motors are shown in Figure 17–15. One motor is called the transmitter, and the other is called the receiver. Stators S1, S2, and S3 of the transmitter are connected to S1, S2, and S3, respectively, of the receiver. The rotors (R1 and R2) are tied together and are connected in common to an alternating-current source.

The transmitter can be turned by either manual or mechanical means. As it turns, the rotor follows at the same speed and in the same direction. The terms transmitter and receiver can be used interchangeably. Either selsyn can be the active transmitter or the passive receiver.

OPERATION

Figure 17–16 shows the vector relationships between the induced voltages of the stator for different positions of the rotor.

Case I

The rotor is lined up with coil S3, resulting in the maximum magnetic coupling. There is a maximum induced voltage in S3 and a partial induced voltage in both S1 and S2. Refer to the vector diagram and note that the resultant field of stators S1, S2, and S3 lines up with the rotor field R1.

Case II

The rotor is now in a position 30° from S3. Therefore, no voltage is induced in S1. A partial voltage is induced in S2 and S3. Again, the resultant field of stators S1, S2, and S3 lines up with rotor field R1.

The rotor is now lined up on the X axis. The polarity of S1 changes because the south pole of the rotor induces a north pole in S1. In cases I and II, the north pole of the rotor induces a south pole in S1. The change in polarity of S1 means that its vector must be reversed. Thus, the resultant field vector lines up with the rotor field R1.

Figure 17–14 shows that the three legs of each stator winding are connected in wye. The three voltages induced in the legs of the secondary windings are not equal in value. These voltages vary with the position of the rotor.

When the two rotors are in exactly corresponding positions, the voltages induced in the transmitter secondary winding are equal and opposite to those induced in the receiver secondary windings. Therefore, there is no current in the secondary windings.

If the transmitter rotor is moved from its original position, the induced voltages are not equal and opposite. As a result, current flows in the secondary or stator windings. This current sets up a torque. Because of this torque, the receiver rotor moves to the same position as the transmitter rotor.