PROCEDURE FOR MEASURING MOTOR LOSSES

On many occasions, it is necessary to measure the losses of a squirrel-cage induction motor to determine the motor output and efficiency. The two types of losses for this motor are the copper losses and the fixed losses. The output of the motor is equal to the input of the motor minus the losses.

For example, assume that a test is made of a three-phase, squirrel-cage induction motor. The motor is rated at 5 hp, 220 V, 13.3 A, 1735 r/min, and 60 Hz. The motor has four poles and is wye-connected.

Equivalent Resistance

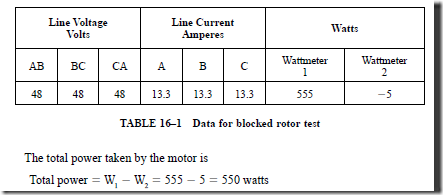

The first step is to obtain the equivalent resistance of the motor windings. The three-phase power and current input to the motor are measured with the rotor stationary. A very low value of three-phase voltage, at the rated frequency, is applied to the test circuit. This voltage is increased until the rated current is indicated by the three ammeters. This test is called the blocked rotor test. The data from this test are given in Table 16–1.

Note that the rated current of 13.3 A is achieved at only 48 V, three phase. The core losses are negligible at this low voltage. Therefore, it is assumed that the total power input of 550 W is used to supply the copper losses.

It is now possible to find the “equivalent ac resistance” per phase for the three wye- connected windings. The power loss in one phase winding is I2 R. For the three windings, the power loss is P = 3 I2 R, where W is the power taken by the blocked rotor motor and R is the equivalent resistance per phase:

It is simple to calculate the copper losses for any load current knowing the effective resistance of each single-phase winding.

Stray Power Losses

The stray power losses include mechanical friction losses, windage losses, and iron losses. To measure these losses, the motor is operated at no load with the rated voltage applied to the motor terminals. The data shown in Table 16–2 are the result of this part of the test.

The following procedure is used to determine the fixed losses or the stray power losses. Total power input at no load:

The stray power losses can be measured at no load only. It is assumed that these losses remain nearly constant from no load to full load. This assumption can be made because the speed of a squirrel-cage motor remains almost constant from no load to full load. Also, the magnetizing current is nearly constant throughout the load range of the motor.

Total Losses, Output, and Efficiency

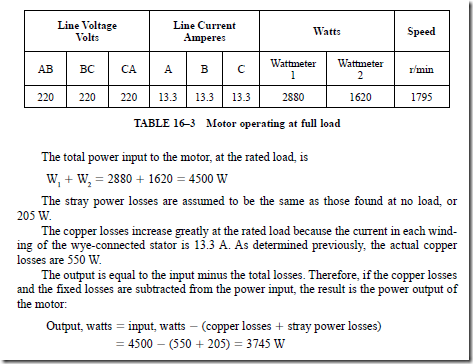

The motor can now be loaded to any desired load point to determine the total losses, the output, and the efficiency. The data obtained with the motor operating at full load are given in Table 16–3.

The discussion on motor losses does not include a detailed study of the variations of certain factors that were assumed to be constants. A more complete study of motor losses can be obtained by consulting electrical engineering texts.

SPEED CONTROL

The synchronous speed of the magnetic field of the stator is determined by the number of stator poles and the frequency of the ac source. Generally, it is not possible to vary the speed of an induction motor by changing its frequency. (Nearly all motors are operated from an ac source having a fixed frequency.) In a few applications, a single alternator may supply one or two motors. In these cases, the frequency can be changed by varying the speed of the prime mover. As a result, the motor speed changes.

Squirrel-cage motors may be provided with special stator windings. When these windings are reconnected by special switch controls, different numbers of stator poles are formed. In this way, different speeds are obtained from a squirrel-cage induction motor connected to an ac source having a fixed frequency.

One type of multispeed squirrel-cage motor is designed for two synchronous speeds, where one speed is twice the other. This two-speed motor has one stator winding. A switch control device is used with this winding to provide two synchronous speeds. For example, speeds of 900 r/min and 1800 r/min may be obtained, or 1800 r/min and 3600 r/min.

Squirrel-cage rotors are not all the same. Rotors are made with different types of bars. The type of rotor bars used in the construction of the rotor determines the operating characteristics of the motor. AC squirrel-cage motors are given a code letter on their nameplate. These code letters should not be confused with the NEMA code letter found on motors manufactured since 1999. The code letter indicates the type of bars used in the rotor. Figure 16–7A shows a rotor with type A bars. A type A rotor has the highest resistance of any squirrel-cage rotor. This means that the starting torque will be high per ampere of starting current because the rotor current is closer to being in phase with the induced voltage than any other type of rotor. Also, the high resistance of the rotor bars limits the amount of current flow in the rotor when starting. This produces a low starting current for the motor. A rotor with type A bars has very poor running characteristics, however. Because the bars are resistive, a large amount of voltage will have to be induced into the rotor to produce an increase in rotor current and, therefore, an increase in the rotor magnetic field. This means that when load is added to the motor, the rotor must slow down a great amount to produce enough cur- rent in the rotor to increase the torque. Motors with type A rotors have the highest per- cent slip of any squirrel-cage motor. Motors with type A rotors are generally used in applications where starting is a problem, such as a motor that must accelerate a large flywheel from 0 r/min to its full speed. Flywheels can have a very large amount of inertia, which may require several minutes to accelerate them to their running speed when they are stated.

Figure 16–7B shows a rotor with bars similar to those found in rotors with code letters B through E. These rotor bars have lower resistance than the type A rotor. Rotors of this type have fair starting torque, low starting current, and fair speed regulation.

Figure 16–7C shows a rotor with bars similar to those found in rotors with code letters F through V. This rotor has low starting torque per ampere of starting cur- rent. The starting current is high, and these motors exhibit good running torque. Motors containing rotors of this type generally have very good speed regulation and low percent slip. It should be noted that although motors with rotors that fall into this range exhibit poor starting torque per ampere of starting current, the starting torque is still greater than the amount of running torque. These motors do not generally exhibit difficulty starting unless the load requires some time to reach normal speed. The extended time will cause the high starting current to overheat the windings.

The Double-Squirrel-Cage Rotor

Some motors use a rotor that contains two sets of squirrel-cage windings (Figure 16–8). The outer winding consists of bars with a relatively high resistance located close to the top of the iron core. Because these bars are located close to the surface, they have a relatively low reactance. The inner winding consists of bars with a large cross-sectional area that gives them a low resistance. The inner winding is placed deeper in the core material, which causes it to have a much higher reactance.

This type of rotor has a high starting torque per ampere of starting current, and low starting current. It is constructed with small rotor bars located near the surface of the rotor. It is used in motors that power metal shears, punch presses, and metal drawing equipment.

This type of rotor exhibits high reactance and low resistance. Motors with rotors of this type have relatively low starting current and fair starting torque per ampere of starting current. They are generally used for motor generator sets, blowers, centrifugal pumps, and other applications that do not require high starting torque.

FIGURE 16–7 Various types of squirrel-cage rotors (Delmar/Cengage Learning)

When the double-squirrel-cage motor is started, the rotor frequency is high. Because the inner winding is inductive, its impedance will be high as compared to the resistance of the outer winding. During this period of time, most of the rotor current flows through the outer winding. The resistance of the outer winding limits the cur- rent flow through the rotor, which limits the starting current to a relatively low value. Because the current is close to being in phase with the induced voltage, the rotor flux and stator flux are close to being in phase with each other, and a strong starting torque is developed. The starting torque of a double-squirrel-cage motor can be as high as 250% of rated full-load torque.

When the rotor reaches its full-load speed, rotor frequency decreases to 2 or 3 Hz. The inductive reactance of the inner winding has now decreased to a low value. Most of the rotor current now flows through the low-resistance inner winding. This type motor has good running torque and excellent speed regulation.

MOTOR NAMEPLATE DATA

The data contained on the typical nameplate for a squirrel-cage induction motor include the following items: horsepower rating, full-load speed, full-load amperes, volt- age, number of phases, frequency, frame number, permissible temperature rise, model number, manufacturer name, locked-rotor ampere code letter, service factor, and NEMA code letter. The NEMA code letter should not be confused with the code letter for locked- rotor amperes. The NEMA code letter is used to determine the fuse or circuit breaker

size for the motor circuit. The locked-rotor amperes code letter describes the type of bars in the rotor and is used in conjunction with NEC® Section 430 to determine the starting current of the motor. A typical nameplate for a squirrel-cage induction motor is shown in Figure 16–9.

STATOR WINDING CONNECTIONS

Many of the three-phase motors used in industry are designed to be operated on two voltages, such as 240 or 480 V. Motors of this type contain two sets of windings per phase. Most dual voltage motors bring out nine T leads at the terminal box. There

is a standard method used to number these leads, as shown in Figure 16–10. Starting with terminal 1, the leads are numbered in a decreasing spiral. Another method of determining the proper lead numbers is to add three to each terminal. For example, starting with lead 1, add three to one. Three plus one equals four. The phase winding that begins with 1 ends with 4. Now add three to four. Three plus four equals seven. The beginning of the second winding for phase one is seven. This method will work for the windings of all phases. If in doubt, draw a diagram of the phase windings and number them in a spiral.

Three-phase motors can be constructed to operate in either wye or delta. If a motor is to be connected to high voltage, the phase windings will be connected in series. In Figure 16–11, a schematic diagram and terminal connection chart for high voltage are

shown for a wye-connected motor. In Figure 16–12, a schematic diagram and terminal connection chart for high voltage are shown for a delta-connected motor.

When a motor is to be connected for low-voltage operation, the phase windings must be connected in parallel. Figure 16–13 shows the basic schematic diagram for a wye-connected motor with parallel phase windings. In actual practice, however, it is not possible to make this exact connection with a nine-lead motor. The schematic shows that terminal 4 connects to the other end of the phase windings that starts with terminal 7. Terminal 5 connects to the other end of winding 8, and terminal 6 connects to the other end of winding 9. In actual motor construction, the opposite ends of windings 7, 8, and 9 are connected together inside the motor and are not brought outside the motor case. The problem is solved, however, by forming a second wye connection by connecting terminals 4, 5, and 6 together, as shown in Figure 16–14.

The phase winding of a delta-connected motor must also be connected in parallel for use on low voltage. A schematic for this connection is shown in Figure 16–15. A connection diagram and terminal connection for this hookup is shown in Figure 16–16.

Some dual-voltage motors will contain twelve T leads instead of nine. In this instance, the opposite ends of terminals 7, 8, and 9 are brought out for connection. Figure 16–17 shows the standard numbering for both delta- and wye-connected motors. Twelve leads are brought out if the motor is intended to be used for wye–delta starting. When this is the case, the motor must be designed for normal operation with its windings connected in delta. If the windings are connected in wye during starting, the starting current of the motor is greatly reduced.