AUTOTRANSFORMERS

The conventional transformer has separate primary and secondary windings that are electrically insulated from each other. The autotransformer, on the other hand, has a primary winding and a secondary winding in the form of one continuous winding. This winding is tapped at certain points to obtain the desired voltages. The winding is wound on a laminated silicon steel core. Therefore, the primary and secondary sections of the winding are in the same magnetic circuit.

Figure 15–8 shows how the autotransformer is connected into a typical circuit. The autotransformer can be viewed as having a primary side of terminals 1–3 and a secondary side of terminals 2–3. The calculations necessary for autotransformer circuits involve two new quantities: conductive power and transformed power.

Conductive power is the product of the current conducted to the secondary side from the primary side and the voltage on the secondary side.

Transformed power is the product of the difference between the primary and secondary voltages and the secondary current.

As an example of the calculation of these power values, consider the circuit shown in Figure 15–8. The 240-V input is connected across the entire winding at terminals 1 and 3.

Figure 15–8 indicates that 18 A is supplied from the source to terminal 1. This cur- rent passes from terminal 1 down through the winding to terminal 2. Note that the load requires 24 A. As a result, there must be a current of 6 A up from terminal 3 to terminal 2 at this same instant: 6 A + 18 A 24 A, as required by the load. The current entering terminal 1 is 18 A at a potential of 240 V. The current at terminal 2 is at a potential of only 180 V. There is a potential drop of 60 V between terminals 1 and 2. This change represents a power value of 60 X 18 = 1080 W. This power is the transformed power. The product of 180 V and 6 A also equals 1080 W. The section of the winding between terminals 1 and 2 represents the primary winding with an input of 1080 W. The section of the winding between terminals 3 and 2 represents the secondary winding with an output of 1080 W.

The 1080-W output provides only a part of the power required by the load. The load requires a total of 4320 W. The 18-A current from terminal 1 leaves the winding at terminal 2 at a potential of 180 volts. The product of 180 V and 18 A is a part of the power, in watts, that is conducted directly through a section of the windings to supply the load:

This value of power is the conductive power. The sum of the transformed power and the conductive power equals the total power supplied to the load, or 4320 W:

Output, watts transformed power + conductive power

3240 W + 1080 W 4320 W

Autotransformer Used to Step Up Voltage

The autotransformer can also be used to step up a voltage. If, in Figure 15–8, a voltage of 180 V is impressed across the section of the winding from terminals 2 to 3, the output voltage across terminals 1 and 3 will be 240 V.

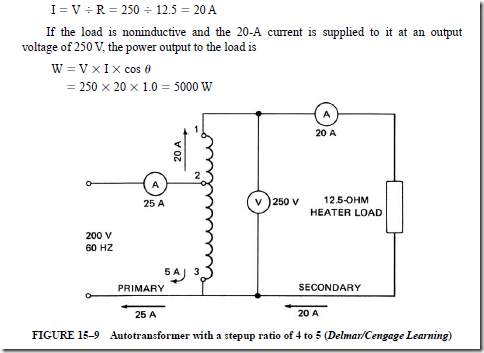

An autotransformer used to step up a voltage is shown in Figure 15–9. A heating load is connected across the full winding, which has an output of 250 V. The current supplied to the load is

This means that if losses are neglected, the input to the transformer will be 5000 W. The current input to the autotransformers at an input voltage of 200 V can be found knowing the power input:

It is assumed that the line wire connected to terminal 2 is negative. A cur- rent of 25 A enters the winding at terminal 2. The load connected between terminals 1 and 3 requires only 20 A. Therefore, 20 A appears in the winding from terminal 2 to terminal 1. The remaining 5 A at terminal 2 appears in the winding between terminal 2 and terminal 3. Between terminal 2 and terminal 3, there is a loss of 200 V at 5 A. This change represents a transfer of 1000 W of power from the winding between terminals 2 and 3 to the flux of the core. Therefore, this section of the coil is the primary winding with a power input of 1000 W. The 20-A current between terminals 2 and 1 increases in potential by 50 V. The product of 50 V and 20 A is 1000 W. The winding between terminals 2 and 1 is the secondary winding and has a power output of 1000 W. This value is the part of the total power output that is transferred by transformer action from one section of the winding to a second section of the winding. The conductive power is considered to be the actual 20-A current at 200 V between terminals 2 and 1:

As compared to a constant-voltage transformer, the core and the copper losses in an autotransformer are smaller. The autotransformer has a slightly better efficiency than does the conventional transformer. The exciting current and the leakage reactance in the autotransformer are small. Therefore, it is an accepted practice to assume that the input and output are the same.

Applications of Autotransformers

Autotransformers are used in applications requiring small increases or decreases in voltage. Several typical uses of autotransformers are as follows:

• On long single-phase and three-phase distribution lines where the line voltage must be increased to compensate for voltage drops in the line wires

• In electronic circuits where several voltages are required

• In three-phase manual and automatic motor starters to reduce the startup voltage applied to three-phase motors; the decreased voltage reduces the starting current surge

• To provide a multivoltage source, as required by electronics laboratories

Multivoltages from an Autotransformer

Figure 15–10 shows one method of providing a number of voltages from one source. Taps are connected to the single winding of an autotransformer to provide a range of volt- ages, from very low values to values above the input voltage. For example, voltages ranging from 15 to 260 V may be obtained from an autotransformer with a 240-V input. This type of multivoltage supply can be used on some types of single-phase variable-speed motors, such as the repulsion motor. When the tap points are connected to a switching mechanism, a range of above- and below-normal speeds is available from the motor.

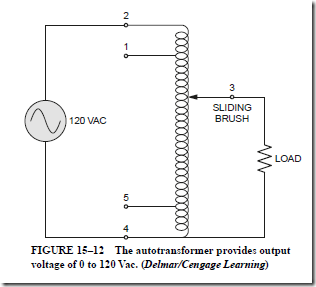

Another common autotransformer is often referred to as a variable transformer. This type of transformer has a sliding brush that can provide any voltage from 0 to full output voltage. The sliding brush permits the turns ratio to be changed to any setting. Many of these transformers can be connected to provide a higher output voltage than the input volt- age. Autotransformers that are connected to 120 Vac can often provide output voltages of 140 Vac. The connection diagram of a variable autotransformer is shown in Figure 15–11. In the circuit shown in Figure 15–12, 120 volts is connected to terminals 2 and 4. The load is connected between the sliding brush connected to terminal 3 and terminal 4. This connection will permit the transformer to supply any voltage between 0 and 120 Vac to the load. If the 120-volt supply is changed to terminals 1 and 4, Figure 15–13, the autotrans- former becomes a stepup transformer.

The autotransformer can now supply 0 to 140 Vac to the load. The part of the wind- ing connected to power is the primary, and the part of the winding connected to the load is the secondary. In Figure 15–13, the primary winding is connected across terminals 1 and 4. Therefore, the winding between these two terminals is the primary. The sliding brush, however, can access all the windings between terminals 4 and 2. The number of turns between terminals 2 and 4 is greater than between terminals 1 and 4, permitting an increase in voltage between terminals 3 and 4. A variable transformer is shown in Figure 15–14.

There are certain applications for which autotransformers should not be used. For example, an autotransformer should not be used to step down 2400 to 120 V for a lighting load. Recall that the primary and secondary windings of the autotransformer are connected electrically through the same winding. Thus, if the low-voltage section is open circuited, the entire high-voltage input will be applied across the low-voltage output.

Possible Hazards with Autotransformers

The normal operation of an autotransformer is shown in Figure 15–15A. Figure 15–15B shows a break in the low-voltage section of the winding. The entire 2400-V input is applied across the break in the winding and across the lighting load. Another voltage hazard will exist if one of the high-voltage leads becomes grounded. In this case, there will be a high voltage between ground and one of the low-voltage wires. Because of these hazards, an autotrans- former is not used in applications requiring a high voltage to be transformed to 120 or 240 V.