THE STATOR WINDINGS

It was stated earlier that the dc armature generates alternating current. If properly connected slip rings are used, instead of a commutator, both alternating voltage and current can be obtained. For a revolving armature type of single-phase alternator having a small capacity and low voltage, the armature winding generally used is the same as that of a dc generator.

Large three-phase, revolving field-type ac generators can use one of several types of stationary armature (stator) windings. These windings generally consist of an even number of coils spaced around the perimeter of the stator core.

The Formed Coil

A typical formed coil is shown in Figure 12–9. Such a coil is machine wound and insulated before it is installed in the slots of the stator core. The coil is sized so that it will span the distance between the poles of opposite polarity. A coil having this dimension is said to have full pitch. A coil smaller than this dimension is said to have fractional pitch. All of the coils of one single-phase winding are collectively known as a phase belt.

Figure 12–10 shows the formed coils of a phase belt (single-phase winding) connected in series. The resulting voltage has the maximum value possible. In Figure 12–11, the same coils are reconnected in parallel to give the maximum current possible, at a lower voltage value.

A three-phase alternator has three separate windings that are placed in the slots of the stator core. The windings are arranged so that three voltages are produced that are 120 electrical degrees apart. Figure 12–12 represents a basic form of a three-phase winding. Three separate single-phase windings are connected in wye. (The three single-phase windings, or phase belts, may be connected in either delta or wye.) The wye connection is used more often than the delta connection because a higher terminal voltage is obtained.

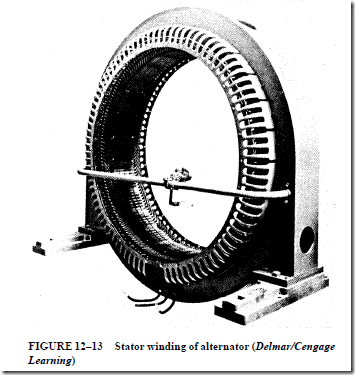

Figure 12–13 shows the stator winding of a three-phase alternator, using a salient pole rotor. Formed coils, similar to the one shown in Figure 12–9, are placed in the slots of the laminated stator core. These coils are connected in three single-phase windings to give three voltages 120 electrical degrees apart. The three phase belts are connected in wye to give a terminal voltage that is 1.732 times the phase winding voltage. The three terminal leads from the stator windings are brought out at the bottom of the stator core. In this location, they can be connected directly to the external three-phase circuit. The flux of the revolving field poles continuously cuts the stator core when the alternator is operating. This action produces induced voltages and the resultant eddy currents in the stator core. These eddy currents can be reduced by the use of a laminated core consisting of thin strips of steel clamped together. The laminated stator is braced with steel channels in the frame. Figure 12–13 shows a typical stator assembly. Note the ventilating ducts in the core of the stator and the ventilating passages in the steel frame. This ventilation prevents the temperature of the stator windings from becoming too high.

The slow-speed alternator shown in Figure 12–13 has a relatively large diameter. Such an alternator is suitable for use with a salient field rotor, similar to the one shown in Figure 12–2.

Stator Windings for Three-Phase Alternator

The stator core and windings shown in Figure 12–14 may be used with a turbine- driven, three-phase alternator. The stator in this case is also laminated to reduce eddy cur- rent losses. Rows of perforations are provided below the teeth of the slots on the core for the windings. These small holes serve as ventilating ducts to circulate air, or hydrogen, to reduce the heat produced in the stator core and windings.

If there is a short circuit, then the resulting short-circuit currents are great enough to stress the end connections. These current stresses can twist and tear the coil ends from the normal positions. To prevent this, special bracing is used for the coil ends, as shown in Figure 12–14.

The diameter of the stator core and windings for a turbine-driven, three-phase alternator is relatively small. The rotor that is used with the stator of Figure 12–14 is a cylindrical nonsalient type, as shown in Figure 12–1.

VENTILATION

Ventilation is not a problem in the operation of salient pole alternators. The salient poles act as fans to circulate the air. Also, large surface areas in this type of alternator are exposed to the surrounding air. Thus, heat is quickly dissipated.

However, high-speed alternators with cylindrical rotors do have ventilation problems. There is almost no fan effect in circulating air with the smooth cylindrical rotor. Only a limited surface area is exposed to the surrounding air in this type of alternator. The stationary armature of this alternator is relatively long, and its diameter is small. To handle the field flux, there must be enough thickness to the laminated stator core in back of the slots. This means that there must be another means of cooling such alternators. The usual method is to completely enclose the alternator with a cooling system using either air or hydrogen. Larger alternators also have hollow conductors through which oil or water can be circulated as a coolant.

Enclosed Cooling System

Most large, high-speed, turbine-driven alternators use a totally enclosed cooling sys- tem with hydrogen as the coolant. There are several reasons why hydrogen is preferred. The density of hydrogen is approximately 10% that of air. This means that the windage losses of the high-speed alternator are reduced. Hydrogen has almost seven times the heat conductivity of air. As a result, there is more effective cooling of the stator core and wind- ings. Disadvantages to the use of hydrogen are that it is explosive and costly to replace. To overcome these problems, a gastight sealing system must be used for the alternator frame. The hydrogen is circulated by a blower system through ducts in the alternator. A water- cooling system is used to cool the machine.

The sinusoidal field voltage shown in Figure 12–15 is induced in the conductors of a stationary armature by the flux of two poles of a rotating field structure. The stationary armature is shown on a horizontal plane. The line of travel of the field poles is also shown on a horizontal plane, moving from right to left. The relative motion between the armature and the field remains unchanged if the armature conductors are viewed as moving from left to right, with the field poles stationary. Using Fleming’s generator rule, it is assumed that the armature conductors are moving to the right in a stationary field. As a result, it can be determined that the induced voltage in armature conductor A tends to drive electrons away from the reader. At the same time, the induced voltage in conductor B causes electrons to move toward the reader. If the two conductors are connected together to make a closed coil loop, these voltages add constructively. The voltage produced depends on the flux density in gauss (B), the active length of the armature conductors (L), and the velocity (v) of the armature conductors:

Note that this is the same formula given earlier in Unit 1. The voltage induced in the coil loop will have a sine-wave pattern if the field poles turn at a constant speed and have a sinusoidal flux distribution.

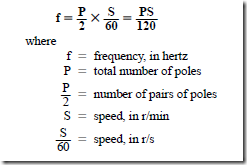

As indicated in Unit 1, the frequency of the induced voltage depends on the number of poles and the speed of the ac generator. When a north pole and a south pole move past a coil, one cycle of voltage is generated. Therefore, the number of cycles of voltage generated in one revolution of the rotating field will be equal to the number of pairs of poles on the rotor. (A pair of poles means one north pole and one south pole.) The frequency of the induced voltage is expressed as follows:

The frequency table in Unit 1 lists the frequencies obtained for different rotor speeds and numbers of field poles.

Controlling the Field Current

The voltage induced in any alternator depends on the field strength and the speed of the rotor. To maintain a fixed frequency, an alternator must operate at a constant speed. Thus, the magnitude of the generated voltage depends on the dc field excitation. A method of changing or controlling the terminal voltage is shown in Figure 12–16.

A rheostat is connected in series with the separately excited field circuit. The three-phase voltage output of the alternator is controlled by adjusting the resistance of the rheostat. If an alternator is operated at a constant speed with a fixed field excitation current, the terminal voltage will change with an increase in the load current. The actual

change in voltage is influenced by the power factor of the load circuit and the impedance of the armature windings.

Effect of the Load Power Factor

In Figure 12–17, the graph shows the effect of the load power factor on the terminal voltage. For each load voltage characteristic curve in Figure 12–17, the alternator field rheostat was adjusted to give the same terminal voltage of 240 V when delivering the full- load current. The term percent voltage regulation is applied to the change in the terminal voltage from a full-load to a no-load condition at a constant speed and a fixed field excitation current.

Percent voltage regulation of an alternator is defined as the percentage change in terminal voltage as the load current is decreased from the full-load value to zero at constant values of speed and field excitation: