A transformer requires an input of alternating current (AC). It transforms the input voltage to one or more output voltages that can be higher or lower.

Transformers range in size from tiny impedance- matching units in audio equipment such as microphones, to multi-ton behemoths that supply high voltage through the national power grids. Almost all electronic equipment that is designed to be powered by municipal AC in homes or businesses requires the inclusion of a transformer.

Two small power transformers are shown in Figure 15-1. The one at the rear is rated to provide 36VAC at 0.8A when connected with a source of 125VAC. At front, the miniature transformer is a Radio Shack product designed to provide approximately 12VAC at 300mA, although its volt age will be more than 16VAC when it is not passing current through a load.

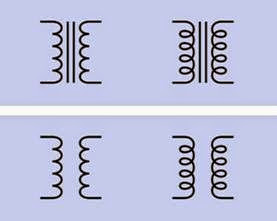

Transformer schematic symbols are shown in Figure 15-2. The different coil styles at left and right are functionally identical. Top: A transformer with a magnetic core—a core that can be magnetized. Bottom: A transformer with an air core. (This type of transformer is rare, as it tends to be less efficient.) The input for the transformer is almost always assumed to be on the left, through the primary coil, while the output is on

Figure 15-1. Two small power transformers. The one at the rear measures approximately 1” × 2” × 2” and is rated to provide 36VAC at 0.8A. The term “sec” on the smaller unit is an abbreviation for “secondary,” referring to the rating for its secondary winding.

the right, through the secondary coil. Often the two coils will show differing numbers of turns to indicate whether the transformer is delivering a reduced voltage (in which case there will be fewer turns in the secondary coil) or an increased voltage (in which case there will be fewer turns in the primary coil).

Figure 15-2. Alternate symbols for a transformer with a ferromagnetic core (top) and air core (bottom). The differing coil symbols at left and right are functionally identi- cal.

How It Works

A simplified view of a transformer is shown in Figure 15-3. Alternating current flowing through the primary winding (orange) induces magnetic flux in a laminated core formed from multiple steel plates. The changing flux induces current in the secondary winding (green), which provides the output from the transformer. (In reality, the windings usually consist of thousands of turns of thin magnet wire, also known as enameled wire; and various different core configurations are used.)

The process is known as mutual induction. If a load is applied across the secondary winding, it will draw current from the primary winding, even though there is no electrical connection be tween them.

In an ideal, lossless transformer, the ratio of turns between the two windings determines whether the output voltage is higher, lower, or the same as the input voltage. If Vp and Vs are the voltages across the primary and secondary windings respectively, and Np and Ns are the number of turns of wire in the primary and secondary windings, their relationship is given by this formula:

Vp / Vs = Np / Ns

Figure 15-3. Three basic parts of a transformer, shown in simplified form.

A simple rule to remember is that fewer turns = lower voltage while more turns = higher voltage.

A step-up transformer has a higher voltage at its output than at its input, while a step-down trans former has a higher voltage at its input than at its output. See Figure 15-4.

In an ideal, lossless transformer, the power input would be equal to the power output. If Vin and Vout are the input and output voltages, and Iin and Iout are the input and output currents, their relationship is given by this formula:

Vin * Iin = Vout * Iout

Therefore, if the transformer doubles the voltage, it allows only half as much current to be drawn from the secondary winding; and if the voltage is cut in half, the available current will double.

Transformers are not 100% efficient, but they can be more than 98% efficient, and relationships between voltage, current, and the number of turns in the windings are reasonably realistic.

When the transformer is not loaded, the primary winding behaves like a simple inductor with re actance that inhibits the flow of current. There fore a power transformer will consume relatively

Figure 15-4. The ratio of input voltage to output voltage is equal to the ratio of primary turns to secondary turns in the transformer windings, assuming a transformer of 100% efficiency.

little electricity if it is left plugged in to an electrical outlet without any load connected to its output side. The power that it does consume will be wasted as heat.

The Core

The ferromagnetic core is often described as being made of iron, but in reality is more often fabricated from high permeability silicon steel. To reduce losses caused by eddy currents, the core is usually laminated—assembled from a stack of plates separated from each other by thin layers of varnish or a similar insulator. Eddy currents tend to be constrained within the thickness of each plate.

Because a DC voltage would cause magnetic saturation of the core, all transformers must operate

with alternating current or pulses of current. The windings and geometry of a transformer are optimized for the frequency range, voltage, and current at which it is designed to operate. Devi ating significantly from these values can damage the transformer.

Taps

A tap on a transformer is a connection part-way through the primary or (more often) the secondary coil. On the primary side, applying an input between the start of a coil and a tap part-way through the coil will reduce the number of turns to which the voltage is applied, therefore in creasing the ratio of output turns to input turns, and increasing the output voltage. On the sec ondary side, taking an output between the start of a coil and a tap part-way through the coil will reduce the number of turns from which the volt age is taken, therefore decreasing the ratio of output turns to input turns, and decreasing the output voltage. This can be summarized:

• A tap on the primary side can increase out put voltage.

• A tap on the secondary side can provide a decreased output voltage.

In international power adapters, a choice of input voltages may be allowed by using a double- throw switch to select either the whole primary winding, or a tapped subsection of the winding. See Figure 15-5. Modern electronics equipment often does not require a voltage adapter, be cause a voltage regulator or DC-DC converter inside the equipment will tolerate a wide range of input voltages while providing a relatively constant output voltage.

A transformer’s secondary winding is often tapped to provide a choice of output voltages. In fact, most power transformers have at least two outputs, since the cost of adding taps to the sec ondary winding is relatively small. As an

Chapter 15

Figure 15-5. An international power adapter can provide a fixed output voltage by using a double-throw switch to apply 230VAC voltage across a transformer’s primary winding, or 115VAC to a tapped midpoint of the primary winding.

alternative to tapped outputs, two or more separate secondary windings may be used, allowing the outputs to be electrically isolated from each other. See Figure 15-6.

Figure 15-6. Multiple output voltages may be obtained from a transformer by tapping into the secondary winding (top) or using two or more separate secondary windings (bottom), in which case the outputs will be electrically isolated from each other.

If the winding on the primary side of a trans former is coiled in the same direction as the winding on the secondary side, the output volt age will be 180 degrees out of phase with the

input voltage. In schematics, a dot is often placed at one end of a transformer coil to indicate where the coil begins. If the dots on the primary and secondary sides are at the same ends of the coils, there will be a 180 degree phase difference be tween input and output. For many applications (especially where the output from a power trans former is going to be converted to DC), this is immaterial.

If there is a center tap on the secondary winding, and it will be referenced as ground, the voltages relative to it, at opposite ends of the secondary winding, will be out of phase. See Figure 15-7.

Variants

Core Shapes

The shell core is a closed rectangle, as shown in Figure 15-3. This is the most efficient but most costly to manufacture. A C-shaped core is another option (three sides of the rectangle) and an E- I core is popular, consisting of a stack of E-shaped plates with two coils wound around the top and bottom legs of the E, or wound concentrically around the center leg of the E. An additional stack of straight plates is added to close the gaps in the E and form a magnetic circuit.

In Figure 15-8, the small transformer from Figure 15-1 has been sliced open with a band saw and a belt sander to reveal a cross-section of its windings. This clearly shows that its primary and secondary windings are concentric. It also reveals the configuration of its core, which is in the E-I format. In Figure 15-9, the E-I configuration is highlighted to show it more clearly.

Power Transformer

Typically designed to be bolted onto a chassis or secured inside the case or cabinet housing a piece of electrical equipment with solder tabs or connectors allowing wires to connect the trans former to the power cord, on one side, and acir

Figure 15-7. A dot indicates the start of each winding. Where primary and secondary windings are in the same direction, the voltage output will be 180 degrees out of phase with the input. Where the dots indicate windings in opposite directions, the voltage output will have the same phase as the input. Where a center tap on the secondary winding serves as a common ground, the voltages at opposite ends of the secondary winding will be opposite to each other in phase.

cuit board, on the other side. Smaller power transformers such as the one in Figure 15-1 have “through-hole” design with pins allowing them to be inserted directly onto circuit boards.

Plug-in Transformer

Usually sealed in a plastic housing that can be plugged directly into a wall power outlet. They are visually identical to AC adapters but have an AC output instead of a DC output.

Figure 15-8. The small transformer from the first figure in this entry is shown sliced open to reveal its internal config- uration.

Figure 15-9. The “EI” shaped plates that form the core of the transformer are outlined to show their edges.

Isolation Transformer

Also known as a 1:1 transformer because it has a 1:1 ratio between primary and secondary windings, so that the output voltage will be the same as the input voltage. When electrical equipment is plugged into the isolation transformer, it is separated from the electrical ground of AC power wiring. This reduces risk when working on

“live” equipment, as there will be negligible electrical potential between itself and ground. Consequently, touching a grounded object while al so touching a live wire in the equipment should not result in potentially lethal current passing through the body.

Autotransformer

This variant uses only one coil that is tapped to provide output voltage. Mutual induction occurs between the sections of the coil. An autotrans former entails a common connection between its input and output, unlike a two-coil transform er, which allows the output to be electrically isolated from the input. See Figure 15-10. Auto transformers are often used for impedance matching in audio circuits, and to provide output voltages that differ only slightly from input voltages.

Figure 15-10. An autotransformer contains only one coil and core. A reduced output voltage can be obtained by tapping into the coil. A common connection prevents the output from being electrically isolated from the input.

Variable Transformer

A variable transformer, also known as a variac, resembles a wire-wound potentiometer. Only one winding is used. A wiper can be turned to contact the winding at any point, and serves as a movable tap. Like an autotransformer, a variable transformer entails a common connection between input and output.

Audio Transformer

When a signal is transmitted between two stages of a circuit that have different impedance, the signal may be partially reflected or attenuated. (Impedance is measured in ohms but is different from DC electrical resistance because it takes into account reactance and capacitance. It therefore varies with frequency.)

A device of low input impedance will try to draw significant current from a source, and if the source has high output impedance, its voltage will drop significantly as a result. Generally, the input impedance of a device should be at least 10 times the output impedance of the device that is trying to drive it. Passive components (resistors, and/or capacitors, and/or coils) can be used for impedance matching, but in some situations a small transformer is preferable.

If Np and Ns are the number of turns of wire in the transformer primary and secondary windings, and Zp is the impedance of a device (such as an audio amplifier) driving the transformer on its primary side, and Zs is the impedance of a device (such as a loudspeaker) receiving power from the secondary side:

Np / Ns = √(Zp / Zs)

Suppose that an audio amplifier with rated out put impedance of 640Ω is driving a loudspeaker with 8Ω impedance. A matching transformer would be chosen with a ratio of primary turns to secondary turns give by:

√(640/8) = √80 = approximately 9:1

The two transformers in Figure 15-11 are through-hole components designed for telecommunications purposes, but are capable of passing audio frequencies and can be used for impedance matching in applications such as a preamplifier.

Figure 15-11. Through-hole transformers. See text for de- tails.

In Figure 15-12, the transformers are designed for audio coupling. The one on the right has impedances of 500 ohms (primary) and 8 ohms (secondary). On the left is a fully encapsulated line matching transformer with a 1:1 turns ratio.

Figure 15-12. Through-hole transformers. See text for de- tails.

Split-Bobbin Transformer

This variant has primary and secondary coils mounted side by side to minimize capacitive coupling.

Surface-Mount Transformer

May be less than 0.2” square and is used for impedance matching, line coupling, and filtering. Two surface-mount transformers are shown in Figure 15-13.

Figure 15-13. Two surface-mount transformers, each measuring less than 0.2” square, typically used in communications equipment and suited for frequencies higher than 5 MHz.

Values

When selecting a power transformer, its power handling capability is the value of primary inter est. It is properly expressed by the term VA, de rived from “volts times amps.” VA should not be confused with watts because watts are measured instantaneously in a DC circuit, whereas in an AC circuit, voltage and current are fluctuating con stantly. VA is actually the apparent power, taking reactance into account.

The relationship between VA and watts will vary depending on the device under consideration. In a worst-case scenario:

W = 0.65 VA (approximately)

In other words, the averaged power you can draw from a transformer should be no less than two- thirds of its VA value.

Transformer specifications often include input voltage, output voltage, and weight of the component, all of which are self-explanatory. Coupling transformers may also specify input and output impedances.

For most electronic circuits, a power transformer will be followed by a rectifier to convert AC to DC, and capacitors to smooth fluctuations in the supply. Using a prepackaged power supply or AC adapter that already contains all the necessary components will be more time-effective and probably more cost-effective than building a power supply from the ground up. See Chap ter 16.

What Can Go Wrong

Suppose a transformer is designed to provide an output voltage of 10 volts from domestic AC power of 115 volts. If the wrong side of the trans

former is connected with 115VAC by mistake, the

output will now be more than 1,000 volts—easily enough to cause death, quite apart from destroying components that are connected with it. Reversing the transformer in this way may also destroy it. Extreme caution is advisable when making connections with power transformers. A meter should be used to check output voltage. All devices containing transformers should be fused on the live side and grounded.

Shock Hazard from Common Ground

When working on equipment that uses an auto transformer, the chassis will be connected through the transformer to one side of 115VAC power. So long as a plug is used that prevents reversed polarity, the chassis should be “neutral.” However, if an inappropriate power cord is used, or if the power outlet has been wired incorrectly, the chassis can become live. For protection, be fore working on any device that uses 115VAC power with an autotransformer, plug the device into an isolation transformer, and plug the isolation transformer into the wall outlet.

Accidental DC Input

If DC current is applied to the input side of a transformer, the relatively low resistance of the primary coil will allow high current that can de story the component. Transformers should only be used with alternating current.

Overload

If a transformer is overloaded, heat will be generated that may be sufficient to destroy the thin layers of insulation between coil windings. Con sequently, input voltage can appear unexpect edly on the output side. Transformers with a tor oidal (circular) core are especially hazardous in this respect, as their primary and secondary windings usually overlap.

Some (not all) power transformers contain a ther mal fuse that melts when it exceeds a temperature threshold. If the fuse is destroyed, the trans former must be discarded.

The consequences of moderate overloading may not be obvious, and can be cumulative over time. Ventilation or heat sinkage should be taken into account when designing equipment around a power transformer.

Incorrect AC Frequency

Single-phase AC power in the United States fluctuates at 60Hz, but Great Britain and some other countries use AC power at 50Hz. Many power transformers are rated to be compatible with either frequency, but if a transformer is specifically designed for 60Hz, it may eventually fail by over heating if it is used with a 50Hz supply. (A 50Hz transformer can be used safely with 60Hz AC.)