Properly known as an electromagnetic armature relay to distinguish it from a solid-state relay. However, the full term is very rarely used. It may also be described as an electro mechanical relay, but the term relay is normally understood to mean a device that is not solid state.

What It Does

A relay enables a signal or pulse of electricity to switch on (or switch off ) a separate flow of electricity. Often, a relay uses a low voltage or low current to control a higher voltage and/or higher current. The low voltage/low current signal can be initiated by a relatively small, economical switch, and can be carried to the relay by relatively cheap, small-gauge wire, at which point the relay controls a larger current near to the load. In a car, for example, turning the ignition switch sends a signal to a relay positioned close to the starter motor.

While solid-state switching devices are faster and more reliable, relays retain some advantages. They can handle double-throw and/or multiple- pole switching and can be cheaper when high voltages or currents are involved. A comparison of their advantages relative to solid state re lays and transistors is tabulated in the entry on bipolar transistor in Figure 28-15.

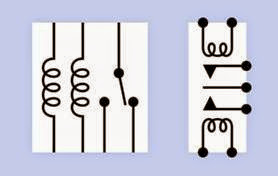

Common schematic symbols for single-throw re lays are shown in Figure 9-1 and for double-

throw relays in Figure 9-2. The appearance and orientation of the coil and contacts in the symbols may vary significantly, but the functionality remains the same.

Figure 9-1. Commonly used schematic symbols for a SPST relay. The symbols are functionally identical.

Figure 9-2. Commonly used schematic symbols for a SPDT relay. The symbols are functionally identical.

How It Works

A relay contains a coil, an armature, and at least one pair of contacts. Current flows through the coil, which functions as an electromagnet and generates a magnetic field. This pulls the armature, which is often shaped as a pivoting bracket that closes (or opens) the contacts. These parts are visible in the simplified rendering of a DPST relay in Figure 9-3. For purposes of identification, the armature is colored green, while the coil is red and the contacts are orange. The two blue blocks are made of an insulating material, the one on the left supporting the contact strips, the one on the right pressing the contacts together when the armature pivots in response to a magnetic field from the coil. Electrical connections to the contacts and the coil have been omitted for simplicity.

Figure 9-3. This simplified rendering shows the primary parts of a DPST relay. See text for details.

Various small relays, capable of handling a variety of voltages and currents, are pictured in Figure 9-4. At top-left is a 12VDC automotive re lay, which plugs into a suitable socket shown immediately below it. At top-right is a 24VDC SPDT

relay with exposed coil and contacts, making it suitable only for use in a very clean, dry environment. Continuing downward, the four sealed re lays in colored plastic cases are designed to switch currents of 5A at 250VAC, 10A at 120VAC, 0.6A at 125VAC, and 2A at 30VDC, respectively. The two blue relays have 12VDC coils, while the red and yellow relays have 5V coils. All are nonlatching, except for the yellow relay, which is a latching type with two coils. At bottom-left is a 12VDC relay in a transparent case, rated to switch up to 5A at 240VAC or 30VDC.

Figure 9-4. An assortment of small DC-powered relays. See text for details.

The configuration of a relay is specified using the same abbreviations that apply to a switch. SP, DP, 3P, and 4P indicate 1, 2, 3, or 4 poles (relays with more than 4 poles are rare). ST and DT indicate single-throw or double-throw switching. These abbreviations are usually concatenated, as in 3PST or SPDT. In addition, the terminology Form

A (meaning normally open), Form B (normally closed), and Form C (double-throw) may be used, preceded by a number that indicates the number of poles. Thus “2 Form C” means a DPDT relay.

Variants

Latching

There are two basic types of relay: latching and nonlatching. A nonlatching relay, also known as a single side stable type, is the most common, and resembles a momentary switch or pushbutton in that its contacts spring back to their default state when power to the relay is interrupted. This can be important in an application where the re lay should return to a known state if power is lost. By contrast, a latching relay has no default state. Latching relays almost always have double- throw contacts, which remain in either position without drawing power. The relay only requires a short pulse to change its status. In semiconductor terms, its behavior is similar to that of a flip-flop.

In a single-coil latching relay, the polarity of volt age applied to the coil determines which pair of contacts will close. In a dual-coil latching relay, a second coil moves the armature between each of its two states.

Schematic symbols for a dual-coil latching relay are shown in Figure 9-5. Some symbol styles do not make it clear which switch position each coil induces. It may be necessary to read the manufacturer’s datasheet or test the relay by applying its rated voltage to randomly selected terminal pairs while testing for continuity between other terminal pairs.

Polarity

There are three types of DC relay. In a neutral re lay, polarity of DC current through the coil is irrelevant. The relay functions equally well either way. A polarized relay contains a diode in series with the coil to block current in one direction. A biased relay contains a permanent magnet near the armature, which boosts performance when

Figure 9-5. Schematic symbols for a two-coil latching re- lay. The symbols are functionally identical.

current flows through the coil in one direction, but blocks a response when the current flows through the coil in the opposite direction. Manufacturers’ datasheets may not use this terminology, but will state whether the relay coil is sensitive to the polarity of a DC voltage.

All relays can switch AC current, but only an AC relay is designed to use AC as its coil current.

Pinout Variations

The layout and function of relay pins or quick connects is not standardized among manufacturers. Often the component will have some indication of pin functions printed on it, but should always be checked against the manufacturer’s datasheet and/or tested for continuity with a meter.

Figure 9-6 shows four sample pin configurations, adapted from a manufacturer’s datasheet. These configurations are functionally quite different, although all of them happen to be for DPDT re lays. In each schematic, the coil of the relay is shown as a rectangle, while the pins are circles, black indicating an energized state and white in dicating a non-energized state. The bent lines show the possible connections between the poles and other contacts inside the relay. The contacts are shown as arrows. Thus, pole 4 can connect with either contact 3 or contact 5, while pole 9 can connect with either contact 8 or con tact 10.

Top-left: Polarized nonlatching relay in its resting condition, with no power applied. Top right: Single-coil latching relay showing energized contacts (black circles) when the coil is powered with the polarity indicated. If the polarity is re versed, the relay flips to its opposite state. Some manufacturers indicate the option to reverse po larity by placing a minus sign alongside a plus sign, and a plus sign alongside a minus sign. Bottom-left and bottom-right: Polarized latching relays with two coils, with different pinouts.

Figure 9-6. Relay pinouts depicted in the style commonly found in manufacturers’ datasheets, showing different re- lay types. Top-left: Single coil, non latching. Top-right: Sin- gle coil, latching. Bottom left: Two-coil, latching. Bottom right: Two-coil, latching, alternate pinouts. (Adapted from a Panasonic datasheet.)

In these diagrams, the relay is seen from above. Some datasheets show the relay seen from be low, and some show both views. Some manufacturers use slightly different symbols to indicate interior functions and features. When in doubt, use a meter for verification.

Reed Relay

A reed relay is the smallest type of electromechanical relay with applications primarily in test equipment and telecommunications. With a coil resistance ranging from 500 to 2000 ohms, these relays consume very little power. The design con

sists of a reed switch with a coil wrapped around it. Figure 9-7 shows a simplified rendering. The two black contacts are enclosed in a glass or plastic envelope and magnetized in such a way that a magnetic field from the surrounding coil bends them together, creating a connection. When power to the coil is disconnected, the magnetic field collapses and the contacts spring apart.

Figure 9-7. This simplified rendering shows a reed relay, consisting of a magnetized reed switch inside a glass or plastic pod, activated by a coil wrapped around it.

In Figure 9-8, two reed relays are shown, at top- left and center-right. At bottom-left, the type of relay on the right has been opened by a belt sander to reveal its copper coil and inside that, a capsule in which the relay contacts are visible.

Surface-mount reed relays can be smaller than 0.5” × 0.2”. Through-hole versions are often around 0.7” × 0.3” with pins in two rows, though some are available in SIP packages.

Reed relays have limited current switching capacity and are not suitable to switch inductive loads.

Small Signal Relay

A small signal relay is also known as a low signal relay. This type may have a footprint as small as a reed relay but generally stands slightly taller, requires slightly more coil current, and is avail able in versions that can switch slightly higher

Figure 9-8. Three reed relays, one of which has had its packaging partially removed by a belt sander to reveal its copper coil and internal contacts.

voltages and currents. There are usually two rows of pins, spaced either 0.2” or 0.3” apart. The red and orange relays in Figure 9-4 are small signal relays.

Automotive Relays

An automotive relay is typically packaged in a cube-shaped black plastic case with quick- connect terminals at the bottom, typically plugged into a socket. Naturally they are designed to switch, and be switched by, a 12VDC supply.

General Purpose/Industrial

These relays cover a very wide range and are usually built without significant concern for size. They may be capable of switching high currents at high voltages. Typically they are designed to plug into a socket such as an octal base of the type that was once used for vacuum tubes. The base, in turn, terminates in solder tabs, screws, or quick connects and is designed to be screwed to a chassis. It allows the relay to be unplugged and swapped without resoldering.

Two industrial relays are shown in Figure 9-9. Both are DPDT type with 12VDC coils and rated to switch up to 10A at 240VAC. The one on the left has an octal base. An octal socket that fits an octal base is shown in Figure 9-10.

Figure 9-9. Two relays powered by 12VDC, capable of switching up to 10A at 240VAC.

Figure 9-10. An octal socket with screw terminals, de- signed to accept a relay with an octal base.

Time Delay Relay

Generally used to control industrial processes, a time delay relay switches an output on and off at

preset time intervals that can be programmed to repeat. The example in Figure 9-11 has a 12VDC coil and is rated to switch up at 10A at 240VAC. It has an octal base.

Figure 9-11. The control switches on a time-delay relay, allowing separately configured “on” and “off” intervals.

Contactor

A contactor functions just like a relay but is de signed to switch higher currents (up to thou sands of amperes) at higher voltages (up to many kilovolts). It may range from being palm-sized to measuring more than one foot in diameter, and may be used to control heavy loads such as very large motors, banks of high-wattage lights, and heavy-duty power supplies.

Values

Datasheets usually specify maximum voltage and current for the contacts, and nominal volt age and current for the coil, although in some cases the coil resistance is stated instead of nominal coil current. The approximate current consumption can be estimated, if necessary, by us

ing Ohm’s Law. The minimum voltage that the relay needs for activation is sometimes described as the Must Operate By voltage, while the Must Release By voltage is the maximum coil voltage that the relay will ignore. Relays are rated on the assumption that the coil may remain energized for long periods, unless otherwise stated.

While the contact rating may suggest that a relay can switch a large load, this is not necessarily true if the load has significant inductance.

Reed relays

Usually use a coil voltage of 5VDC and have a contact rating of up to 0.25A at 100V. Through-hole (PCB) versions may have a coil voltage of 5VDC, 6VDC, 12VDC, or 24VDC and in some cases claim to switch 0.5A to 1A at up to 100V, although this rating is strictly for a non inductive load.

Small signal/low signal relays

Usually use a coil voltage ranging from 5VDC to 24VDC, drawing about 20mA. Maximum switching current for non inductive loads ranges from 1A to 3A.

Industrial/general purpose relays

A very wide range of possible values, with coil voltages ranging up to 48VDC or 125VAC to 250VAC. Contact rating is typically 5A to 30A.

Automotive relays

Coil voltage of 12VDC, and contact rating often 5A at up to 24VDC.

Timer relays

Usually these specify a coil voltage of 12VDC, 24VDC, 24VAC, 125VAC, or 230VAC. The

timed interval can range from 0.1 sec to 9999 hours in some cases. Common values for contact ratings are 5A up to 20A, with a volt age of 125V to 250V, AC or DC.

How to Use it

Relays are found in home appliances such as dishwashers, washing machines, refrigerators, air conditioners, photocopy machines, and other products where a substantial load (such as a motor or compressor) has to be switched on and off by a control switch, a thermostat, or an electronic circuit.

Figure 9-12 shows a common small-scale application in which a signal from a microcontroller (a few mA at 5VDC) is applied to the base of a transistor, which controls the relay. In this way, a logic output can switch 10A at 125VAC. Note the rectifier diode wired in parallel with the relay coil.

Figure 9-12. A signal from a digital source such as a microcontroller can switch substantial voltage and current if it is applied to the base of a transistor that activates a re- lay.

A latching relay is useful wherever a connection should persist when power is switched off or interrupted, or if power consumption must be minimized. Security devices are one common application. However, the circuit may require a “power reset” function to restore known default settings of latched relays.

A circuit including every possible protection against voltage spikes is shown in Figure 9-13, including a snubber to protect the relay contacts, a rectifier diode to suppress back-EMF generated by the relay coil, and another rectifier diode to

protect the relay from EMF generated by a motor when the relay switches it on and off. The snub ber can be omitted if the motor draws a relatively low current (below 5A) or if the relay is switching a noninductive load. The diode around the relay coil can be omitted if there are no semiconduc tors or other components in the circuit that are vulnerable to voltage spikes. However, a spike can affect components in adjacent circuits that appear to be electrically isolated. A severe spike can even be transmitted back into 125VAC house wiring. For information on using a resistor- capacitor combination to form a snubber, see “Snubber” (page 108).

Figure 9-13. This hypothetical schematic shows three types of protection against voltage spikes induced by an inductive load (a motor, in this instance) and the coil of the relay.

What Can Go Wrong

Wrong Pinouts

The lack of standardization of relay pinouts can cause errors if one relay is replaced with another that appears to be the same, but isn’t. In particular, the pins that connect with normally closed contacts may trade places with pins connected with normally-open contacts, in relays from different manufacturers.

Pinouts are also confusing in that some data sheets depict them from above, some from be low, and some from both perspectives.

Wrong Orientation

Small relays of through-hole type usually have pins spaced in multiples of 0.1”. This allows them to be inserted the wrong way around in a perfo rated board. Almost all relays have an identification mark molded into one end or one corner of the plastic shell. Manufacturers do not standardize the position and meaning of these marks, but they are usually replicated in datasheets. When using a relay of a type that you have not used before, it is a sensible precaution to test it with a meter to verify the functions of its terminals be fore installing it.

Wrong Type

A latching relay may have exactly the same appearance as a non latching relay from the same manufacturer, and the same two pins may energize the coil. However, in a latching relay, the contacts won’t spring back to their non- energized position, causing functional errors that may be difficult to diagnose. The part numbers printed on latching and non latching versions of the same relay may differ by only one letter or numeral and should be checked care fully.

Wrong Polarity

A relay with a DC-energized coil may require power to be applied with correct polarity and may malfunction otherwise.

AC and DC

A relay coil designed to be powered by DC will not work from AC and vice-versa. The contact rating of a relay is likely to be different depending whether it is switching AC or DC.

Chatter

This is the noise created by relay contacts when they make rapid intermittent connection. Chatter is potentially damaging to relay contacts and should be avoided. It can also create electrical noise that interferes with other components. Likely correctible causes of chatter include insufficient voltage or power fluctuations.

Relay Coil Voltage Spike

A relay coil is an inductive device. Merely switching a large relay on and off can create voltage spikes. To address this problem, a rectifier diode should be placed across the coil terminals with polarity opposing the energizing voltage.

Arcing

This problem is discussed in the switch entry of this encyclopedia. See “Arcing” (page 47). Note that because the contacts inside a reed relay are so tiny, they are especially susceptible to arcing and may actually melt and weld themselves to get her if they are used to control excessive cur rent or an inductive load.

Magnetic Fields

Relays generate magnetic fields during operation and should not be placed near components that are susceptible.

The reed switch inside a reed relay can be unexpectedly activated by an external magnetic field. This type of relay may be enclosed in a metal shell to provide some protection. The adequacy of this protection should be verified by testing the relay under real-world conditions.

Environmental Hazards

Dirt, oxidation, or moisture on relay contacts is a significant problem. Most relays are sealed and should remain sealed.

Relays are susceptible to vibration, which can affect the contacts and can accelerate wear on

moving parts. Severe vibration can even damage a relay permanently. Solid-state relays (dis cussed in Volume 2) should be used in harsh environments.