Stock Control

The general background

The stock of a shop or firm means all the goods it has for sale. Stock control means managing sensibly the amount of goods in stock. The aims are to:

1 Keep enough of each item in stock so that they do not run out.

2 Avoid having too much of any item.

It is bad for trade to run out of goods a customer wants. It is also bad for profits to have large quantities of items that won’t sell. They take up storage space and represent money spent for no return. All the items which are in stock have had to be bought.

The main jobs of a stock control system are:

1 To keep a check on exactly what goods are in stock.

2 To work out what goods are selling and to fix maximum and minimum stock levels for each item.

3 To reorder goods to replace the items which are sold so that stocks are kept between the maximum and minimum levels.

Example of a stock control system

The following example is about a chain of photographic shops. The shops deal mainly in cameras and photographic materials such as films. They also sell specialized items used for photography such as tripods and camera bags. The company has a computer at its head office, which has a warehouse adjoining it. There is a point of sale terminal in each shop and a terminal in the warehouse (see Figure 2).

The overall system

The computer controls the stock in the shops and in the warehouse (Fig 1). The shops are supplied by a delivery twice weekly from the warehouse. The company orders goods to stock the warehouse from a number of different suppliers.

Fig 1 The supply of goods for a chain of photographic shops

Fig 1 The supply of goods for a chain of photographic shops

The collection and input of data

Data is collected and input:

in the shops

As each item is sold the sales assistant. types in a code for it at the terminal. The terminal contains a microprocessor and some storage. This is used:

1 To store details of all the day’s transactions. These are stored during the day and sent to the main computer in the evening. The terminal is left connected to a telephone line overnight. The main computer phones each terminal in turn automatically for its information. The computer uses the information to keep its file of the stock levels in each shop up to date. In this way the computer has a record of what items should still be on the shelves in the shop.

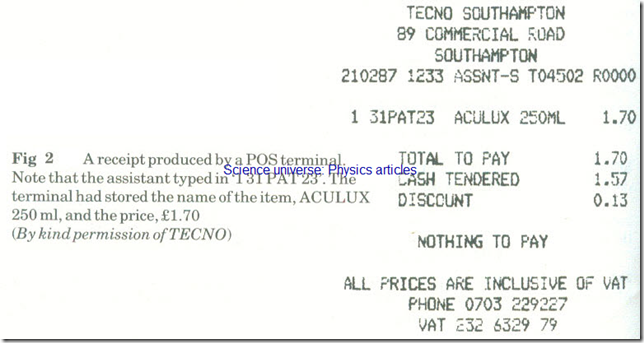

2 To store a list of the names and the prices of most goods in the shop. The terminal uses this when printing the receipt for the customer (Fig. 2).

Fig. 2 A receipt produced by a POS terminal. Note that the assistant typed in ‘131 PAT 23’. The terminal had stored the name of the item, ACULUX 250 ml, and theprice,£1.70

(By kind permission of TECNO)

The sales assistants do sometimes have to fill in forms to be sent to the main computer centre:

1 If a mistake is made in entering data and not discovered until later.

2 If the terminal breaks down.

3 When they do a stock check in the shop-which they do occasionally in case any errors have been made.

At the warehouse

Entries have to be made of goods leaving or arriving:

1 When items are delivered from the suppliers to the warehouse.

2 When items are sent from the warehouse to the shops.

For standard items such as films and cameras a delivery form arrives with the goods from the supplier. The data from this form is then sent to the head office to be input by a keyboard operator working at a YOU.

For special one-off orders the storekeeper keys the details in at the terminal.

in the office

The management make decisions about new products or items which are to be discontinued. This Information is typed into a terminal to update the files.

The files used

1 The stock master file. This contains data on the stock in the warehouse. It has details of all items which are stocked on a regular basis. Each of these is given an item number. The file is a sequential file and is in order of the item numbers. Each record refers to one item and contains:

Item number -this is a key field for the record.

Description of the item -the name and details such as size, etc.

Present stock level -the number of the item in the warehouse.

Reorder level -item is reordered when stock falls below this.

Maximum stock level -used to decide how many to order.

Minimum reorder number – this is the smallest number which can be ordered from the supplier.

Date of previous order

Supplier – this is a code indicating which supplier the item can be

reordered from.

Reorder situation -this is a code indicating whether the goods are discontinued or to be reordered, etc.

2 The suppliers master file. This contains data on all the suppliers which the company uses.

Each record consists of:

Supplier code as stored on the master stock file.

Name and address of the supplier.

Status of orders from that supplier.

3 There is also a stock file kept for each shop. These stocks files are similar to the master file for the warehouse.

The role of the computer

The computer carries out many tasks including:

1 Checking stock levels in each shop and working out what goods are to be sent to the shop.

2 Checking stock levels in the warehouse and working out what goods are to be ordered from the suppliers.

3 Storing orders so that goods from each supplier are together. Producing orders using the suppliers master file.

4 Adjusting stock levels in the files for the warehouse and the shops when a delivery is made from the warehouse to the shop. The computer produces a list of the items to be sent. The storekeeper indicates on the terminal when the items have been sent.

5 Adjusting stock levels in the files for the warehouse when a delivery is made to the warehouse from the suppliers.

Computer output

The computer output includes:

1 Lists of goods to be ordered from each supplier.

2 Lists of goods to be sent to each shop.

3 Records of sales and forecasts for management so that decisions can be made about discounting products and introducing new ones.

Fig 3 System flowchart of stock control system described