The Basic Forms of Duty for Drive Motors

The term "duty" refers to a statement of loads including no-load, rest and de-energized periods, to which the machine or apparatus is subjected, including their duration and sequence in time. With respect to motor drive, three basic forms of duty may be Singled out. They are continuous duty, short-time duty, and intermittent duty.

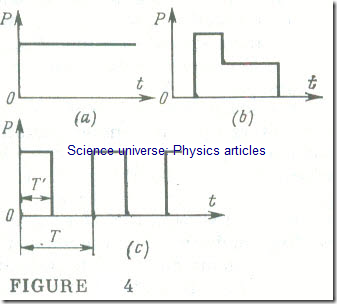

Continuous duty refers to a duty that demands operation at a substantially constant load for a time sufficiently long for all the components of the motor drive to achieve a steady-state temperature (Fig 4 a). Examples of machines operating in continuous duty are centrifugal pumps at pump-houses, fans, blowers, compressors, conveyors, smoke exhausters, paper-making machines, and textile finishing machines.

Short-time duty normally refers to a duty at constant load during a time less than that required to obtain the steady-state temperature in continuous duty at the same load, followed by a rest of sufficient duration to re-establish equality of temperature with the surroundings (Fig 4 b). Examples include motor drives for navigation locks, drawbridges, and aircraft landing gear.

Intermittent duty defines a requirement of service that demands operation for alternate periods of load and no load; load and rest; load, no load and rest. These intervals are such that during load periods the drive motor does not reach a steady-state temperature, whereas during load or rest periods it has no time to re-establish equality of temperature with the surroundings (Fig 4 c). Examples are cranes, rolling mills, oil drilling rigs, and metal-working machine-tools. Data sheets for electric machinery operating in intermittent duty include a very important variable called the duty cycle which is defined as the ratio of a load period to the sum of the load, no-load (and rest) periods, expressed as a percentage.

Knowledge of the expected form of duty is important as it governs the selection of a drive motor in terms of its power rating. Also the conditions in which a drive’ motor operates in intermittent duty will obviously differ from those applicable to a motor intended to run in continuous duty. For example, the cooling conditions for the field winding of a shunt-wound d.c. motor remain practically constant both during the. load and the :rest periods, while the cooling of the armature at rest is gravely impaired. For this reason a d.c. motor designed for continuous duty under unvarying cooling conditions would be a poor choice for use in intermittent duty: at the maximum safe temperature of the armature winding and commutator the field winding would be heated too much below its safe temperature.

For this and some other reasons it does pay to build motors specifically designed for intermittent duty. In fact, crane motors come in three modifications each adapted to a particular form of duty: continuous, short-time, or intermittent. Information to that effect is stated on the nameplate of each motor. In each case, the power rating of a motor refers to the rated power in the respective duty and subject to the duty cycle stated.

Every motor is designed so that it is capable of developing more than its rated power for some time without any damage to itself. This is referred to as overload capacity. It may be classed as instantaneous or as short-time. The instantaneous overload capacity is mostly determined by the electrical properties of the motor (the maximum torque in the case of induction motors or the commutation conditions in the case of d.c. motors). Sometimes, the mechanical design of a motor may also be a factor in this respect. It is customary to define the instantaneous overload capacity of a motor in terms of the overload torque ratio, λT, which is the ratio of the maximum instantaneously safe torque, Tmax , to the rated torque , Trtd, of the motor. For most electric motors λT is about 2 (for special-purpose motors, λT = 3-4).

The short-time overload capacity is an important consideration for motors operated under certain service conditions. This may be the maximum power output considered safe for 5, 10, 15, or 30 min. whichever may be the case. At the end of the specified overload period the motor must be de-energized for a time sufficiently long to re-establish equality of temperature with the surroundings (or the cooling medium). For the same type of motor the relation between its continuous-duty, instantaneous-overload and .short-time overload ratings depends on its characteristics and design.