The Induction Regulator and the Phase Shifter

An induction regulator is essentially a booster transformer constructed in the same way as a three-phase wound-rotor induction motor except that the rotor is not free to rotate; it can, however, be set in a range of orientations with respect to the stator.

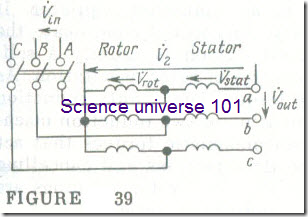

The winding connections in an induction regulator (also called a rotary autotransformer) are shown in Fig 39. The stator and rotor windings in all the three phases are connected in series, with. the supply voltage impressed on the rotor winding.

The basic resemblance between an induction regulator and a three-phase autotransformer will be readily seen if we compare the circuit arrangement of the two. The rotor winding serves a the primary winding of an autotransformer and the three free lead of the stator windings are the secondary (or output) leads. In an autotransformer, however, the primary to secondary voltage ratio is constant and determined by the primary to secondary turn ratio. In an induction regulator the voltage ratio is further dependent on the relative spatial position (relative orientation) of the stator and rotor windings. If the axes of the two winding are in line, the emfs induced in them will, too, be in line. If, on the other hand, the rotating magnetic field cuts the stator winding at a time different from the instant when it cut the rotor winding, the spatial shift between the winding axe will cause a proportional time-phase shift a (see Sec. 14.5) between the tater and rotor emfs and, in consequence, between the stator and rotor voltages, Vstat and Vrot .

The phase voltage on the secondary side of an induction regulator is the sum of the stator and rotor voltages

V̇2 = V̇rot + V̇stat

The rotor is locked, but it can be moved by a worm transmission so that the phase angle between V̇rot and V̇stat is adjusted from 0 to 3600 (Fig 40). As a result, the secondary voltage can be varied from V2 = Vrot – Vstat to V2 = Vrot + Vstat ·

The rotor phase voltage is equal to the supply-line phase voltage, Vrot = Vph, and the stator winding of an induction regulator usually has as many turns as the rotor phase winding has , so Vstat = = Vrot = Vph It follows then that the secondary voltage (the voltage between the stator terminal ), Vout = √3V2 , of an induction regulator can be varied from 0 to 2Vin = 2Vline , twice the line voltage of the supply. In cases involving heavy block of power it is valuable that this voltage adjustment can be effect d without having to make or break any contacts. This materially improve the reliability of operation .

The interaction of the rotor currents with the magnetic field might produce a substantial torque in an induction regulator. If no measures w re taken to the contrary, this would complicate the arrangement of the rotating mechanism (which is usually a self-braking worm transmission) and the control of rotor orientation. As a way of minimizing this undesirable torque, heavy-duty induction regulators are usually made as a combination of two induction machines on a common shaft, with the electromagnetic torques that act on their rotors being oriented in opposite directions and cancelling each other. In such an induction regulator, the rotor windings are connected in paralle1 and the stator windings in series .

As compared with a conventional transformer, an induction regulator ha a markedly lower efficiency due to the pres nee of an air gap in the magnetic circuit. In comparison with a conventional induction motor, an induction regulator has a fairly large loss in the rotor core in addition to the stator core loss. The cooling conditions in an induction regulator are worse than they are in an induction motor because the rotor is at standstill. To rectify the situation, medium- and large-size induction regulators are fitted with oil coolers.

The fact that the rotation of the locked rotor can be used so as to continuously adjust the relative phase of the emfs induced in the rotor is utilized in phase shifters (or, more accurately, phase-shifting transformers). The three-phase stator winding of such a phase shifter, cp, is connected to the supply line, and the locked-rotor winding serves as the secondary winding of a rotary transformer (Fig 41). The rms value of the emf induced in the rotor winding is independent of the rotor orientation because the rotating magnetic field of the machine induced by the stator currents is constant in magnitude. However, the relative phase of the stator and rotor emfs does depend on the rotor orientation. Therefore, by rotating the rotor it is possible to adjust the relative phase anywhere between zero and 360°. Phase shifters (or phase-shifting transformers) are used to test a.c. electricity meters and wattmeters (Fig 41), to control rectifier converters, etc.