Core and Winding Designs

The service conditions in which transformers are used have a direct bearing on the design of their cores, coils, and (in the case of oil-immersed units), oil tanks.

The core of a transformer is built up from electrical-sheet steel laminations 0.35 moo or 0.5 mm thick. The steel usually contains 4-5 % silicon so as to minimize eddy-current losses. Prior to assembly, the punchings are given a coat of varnish on each side for better insulation in the core. The laminations are assembled into blocks in which they are held together by steel bolts insulated from the core material so as not to form closed loops.

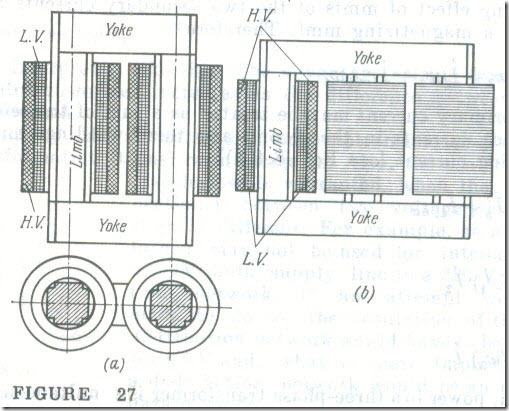

According to the core design, two types of transformers are in common use. When the magnetic circuit takes the form of a single ring encircled by two or more groups of primary and secondary windings distributed around the periphery of the ring, the transformer is termed a core-type transformer (Fig 27). When the primary and secondary windings take the form of a common ring which is encircled by two or more rings of magnetic material distributed around its periphery, the transformer is termed a shell-type transformer (Fig 28).

The magnetic circuit in a core type transformer is made up of limbs (or legs) which carry the windings, and two yokes which complete the magnetic circuit. This form of magnetic circuit is simpler in design than the shell type, and it is easier to provide the right level of insulation for the windings. For these reasons, core-type transformers are the more commonly used of the two designs.

The vertical limbs in a core-type transformer are of multistep cruciform section approaching a circle. This shape has been chosen for better utilization of the window area in the core, and the number of steps increases with increasing power rating of the transformer. It is only in small-size transformers that the limbs are rectangular or square in cross section.

To improve cooling and ventilation in medium- and large-size transformers it is usual to provide oil ducts between the blocks of punchings . The yokes of a core-type transformer may be of a multistep cruciform or rectangular cross section.

An advantage of a shell-type transformer is that its magnetic circuit protects the windings against mechanical injury to some extent. The shell-type core is used in small-size dry transformers.

The joints between the limbs and the yokes in a transformer core may be either of the butt or of the interleaved (or imbricated ) type (Fig .29). The latter type is preferable as it reduces the reluctance at the joints.

The transformer windings, H.V. or L.V., may be concentric or interleaved (or sandwich) types. Concentric windings are used in most transformers. The simplest variety is in the form of cylindrical coils taking up the whole length of, and arranged coaxially on, the same limb (Jabelled I-LV. and L.V. in Fig. 27). The L.V. cylinder is placed next to the limb as it is easier to insulate from the core, and the H.V. cylinder encloses the L.V. winding. The two windings are separated by a synthetic-resin-bonded paper (S.R .B.P.) sleeve or cylinder.

Interleaved (or sandwich) windings are used relatively seldom, and then mostly in shell-type transformers. This type of winding is a series or pancake or disc coils with the primary and secondary sections alternating in an interleaved or sandwich pattern (Fig 28). The outer disc coils next to the yoke are those on the L.V. side.