The Shunt Motor

In a shunt motor, the armature circuit is connected in parallel with the field circuit. Therefore, the field current in a shunt motor is independent of the armature current and the load on the motor.

The basic form of connection for a d.c. motor to a starting rheostat, rs, and a field rheostat, rf is shown in Fig. 37. The function of the starting rheostat is to limit the armature current at starting so long. as the armature emf is zero or very small because, in accord With Eq. (13.6),

Iarm = (V–Earm)/(rarm + rs)

The armature emf Earm is directly proportional to the magnetic flux Φ . It is desired that at starting the armature emf Earm builds up as fast as practicable. For this reason, the shunt field winding should receive full line voltage at starting, with the field rheostat rf brought out of circuit. The driving torque developed by a motor, Eq. (13.2), is likewise directly proportional to the magnetic flux Φ. Therefore when a motor is started at a maximum flux, its torque will also be a maximum. and this will simplify the starting procedure, because the starting current may also go down at a proportionately faster rate.

The required connection of the shunt field winding is shown in Fig. 13.38. The starting rheostat has a metal arc m held in contact with a sliding arm attached to the rheostat knob. So long as the knob is positioned at the dummy contact 0, both the armature circuit and the field circuit of the motor are deenergized . At starting, when the knob is moved from contact to contact. the field winding is receiving full line voltage all the time.

The first contact of the starting rheostat is connected to the metal arc m. so when the motor is turned off, the field winding is shorted through the armature and the starting rheostat. This prevents the occurrence of a large emf which could otherwise be generated as the field circuit is opened. because the field winding has e high inductance. The closed loop containing the starting rheostat converts the energy stored in the magnetic field of the field winding into heat when the motor is stopped, The steps of the starting rheostat are designed so that at normal starting the armature current is not more than twice the rated armature current. When the motor is running , its armature current is I arm = (V – Earm)/rarm.

Since Earm = CE Φn, it follows that

n = ( V – rarmIarm)/CEΦ (13.7)

which is the speed equation for a shunt motor.

The driving torque developed by a shunt motor can he deduced from the general equation of electromagnetic torque, Eq. (13.2), for a d.c. machine

Td = cTΦIarm (13.8)

The driving torque balances the braking torque applied to the shaft (the static moment). .

As the load on the motor shaft is increased, the torque balance IS upset at first, and the motor slows down a little. However. this brings about a reduction in Earm and, in consequence, an increase in [a.rm’ The driving torque builds up in proportion to f 8rm. and the torque balance is restored at a somewhat reduced speed, n. On the basis of Eqs. (13.7) and (13.8), the dependence of n on torque may be written as

n = (V/cEΦ) – Tdrarm/cEcTΦ2 (13.9)

Armature reaction may affect the performance of a motor to some extent. As the armature current Iarm increases, the main magnetic flux (J) decreases (especially so if the motor has no com poles). According to Eq. (13.9), a reduction in the magnetic flux causes the speed to rise, and so it opposes the reduction in speed caused by the increase in rarmIarm On the other hand, the reduction in the magnetic flux reduces the driving torque, so that a greater armature current is needed in order to maintain the torque balance.

Most shunt motors have a compensating winding wound with a small number of turns and intended to cancel out the effect of armature reaction on the main magnetic flux. The compensating winding is connected aiding with the shunt field winding, and has practically no effect on the characteristics of the motor.

For this reason, motors fitted with a series compensating winding are classed as shunt-wound, although actually they use compound excitation. In some special applications, however. this compensating winding must be considered.

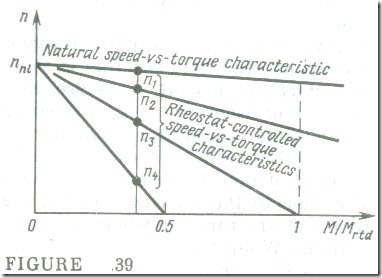

Thus, if we deem the magnetic flux Φ constant, then Eq. (13.9), when plotted, will yield a straight line slightly bent towards the axis of abscissae (Fig. 39). This is the natural speed-us-torque characteristic of a shunt motor. As the load at the shaft varies from zero to full load, the speed of most shunt motors drops by as little as 3-8% (the drop decreases with increasing power rating of the motor). Therefore the natural speed-vs-torque characteristic of a shunt motor may be taken as a flat one.

The slope of the speed-vs-torque characteristic can be varied by placing a rheostat, r, in series with the armature winding. Then the speed equation will take the form

Equation (13.10) defines the speed-vs-armature current characteristic of a shunt motor. By varying the setting of the rheostat r, we can obtain a family of rheostat-controlled speed-us-torque characteristics which are more drooping than the natural speed-vs-torque characteristics. All of these characteristics cut the axis or ordinates at the same point located so that I arm = 0 or Earm = cEnnIΦ= V, where nnI is the armature speed with the motor running under ideal no-load conditions, that is, when the braking torque applied to the shaft is zero. Since the friction in the moving parts of a motor always produces a braking torque, an ideal no-load condition can only be obtained by applying an external driving torque to the shaft from an auxiliary motor.

if, with the torque at the shaft held constant, we gradually increase the resistance of the armature rheostat, the point n indicating the speed of the motor on the diagram of Fig. 39 will move from one curve to another (points n1 through n4). Thus, by varying the setting of the armature rheostat, we can control the speed of the motor. However this form of speed control is uneconomical, because the current flowing through the armature rheostat is equal to the armature current, I arm so the rI2arm loss is considerable. For this reason, armature rheostat speed control is only used on small motors. In fact, the armature rheostat controls the voltage across the armature winding. An advantage of this form of speed control is that the armature current and the torque developed by the motor remain constant. The situation typical of most drives is a constant load torque and a varying speed. Therefore, when a motor is used in such a drive, speed control by change of voltage will not cause any change in the armature current, and the armature winding will not be overloaded. For this reason, this form of control is called constant-maximum torque speed control.

As follows from Eq. (13.10), the speed n is inversely proportional to the main magnetic flux (J), and this flux may be deemed directly proportional to the field current It so long as the magnetic circuit is not saturated. Hence, the speed of a motor can be controlled by varying its field current for which purpose a field rheostat, rf, is inserted in the field circuit. The speed-vs-armature current characteristic is hyperbolic in shape. In Fig. 40, the characteristic is shown for a motor running at no load.

Speed control at a constant braking torque proceeds as follows.

An increase in the resistance of the field rheostat brings down the field current, with the result that the magnetic flux Φ and the armature emf Earrn are decreased. The reduction in Earm leads to an increase in the armature current

Iarm = (V – Earrn)/rarrn

and also in the driving torque and the speed of the motor. This serves to restore both the torque balance and the electric balance

V = Earrn + rarmIarrn

at a higher speed and at a larger armature current. Thus, when the torque is held constant, an increase in the speed of the motor by weakening its magnetic flux brings about an increase in the armature current and leads to an overload at the commutator and in the armature winding.

The situation is different when the driven machinery calls for a constant output power, Pload . Since

Pload = Tɷ = cTΦIarmnπ/30 = kΦIarmn

a decrease in the magnetic flux will bring about an increase in the speed and a decrease in the torque while the armature current remains constant. Thus, speed control by varying the field current is advantageous when the output power remains constant. This form of control is called constant-maximum-power speed control.

The slope of the speed-torque characteristics of a motor is different for different levels of excitation (Fig. 41). Given a constant

torque, T = cTΦI arm , a decrease in the magnetic flux necessitates a proportionate increase in the armature current. In consequence, a change in load brings about a greater change in the speed, n = (V – rarmIarm)/cEΦ. In other words, a reduction in the magnetic flux makes the speed-torque characteristic progressively more drooping.

Since the field current is a mere 2 or 3% of the armature current the additional rfI2f1loss in speed control by weakening the magnetic flux Is relatively small, so this form of speed control is fairly economical. However, an excessive increase in speed may produce an overload current in the commutator and armature, impair the conditions of commutation, give rise to dangerous centrifugal forces in the armature . and so on. For this reason, general-purpose shunt motors are built With speed control in the ratio 2 : 1 as a maximum. Greater ratios of speed control are possible only if suitable changes are made in motor design.

A wider range of speed control and non-rheostat starting for shunt motors Is provided by use of a controlled-voltage source which may be a d.c. machine or a solid-state controlled rectifier. This form of control is especially advantageous for heavy duty, such as rolling mills .

If a d.c. generator is used, the system is called a Ward-Leonard system. As is seen from Fig. 42, it consists of four machines: an induction (or synchronous) motor, IM, which drives at constant speed a large d.c. generator, G, and a small shunt generator which serves as an exciter, Ex., for the package. The armature circuit of the generator is connected across the armature circuit of the controlled motor, M. The field circuits of the generator and motor are energized by the exciter. The speed of the main motor is controlled by controlling solely the field circuits of the machines. The generator voltage is controlled with a rheostat, rf,g, placed in the field circuit of the generator. The rheostat has two contact arms and is connected as a potentiometer, so it ran be used to reverse the field current of the generator. Reversal of the field current reverses the polarity of the voltage at the generator terminals and causes the motor to reverse as well.

When starting the motor, the generator voltage is brought down by adjusting the generator excitation.

For a medium-sized installation, the Ward-Leonard system can control speed in the range from 5: l to 10 : 1. The speed-vs-torque characteristics within that range are parallel straight lines (Fig. 43), but they make a greater angle with the axis of abscissae than the natural speed-torque characteristic of a motor. The reduced flatness of the speed-torque characteristic stems from the reduction in the generator voltage with increasing load due to the effect of the internal armature resistance, rarm,g, of the generator. Hence, the speed equation for the motor in a Ward-Leonard system takes the form

The reduction of the braking torque to zero corresponds to an ideal no-load condition. If we keep applying an external torque (T < 0) to the motor shaft. the motor will change from the motor to the generator mode of operation.

The range of speed control offered by a Ward-Leonard system can be extended still more by varying the field (excitation) current of the motor. By weakening the magnetic flux, speed can be controlled approximately in the ratio 4: 1. Thus, taking a Ward-Leonard system as a whole, the overall range of speed control is from 12: 1 to 16: 1. Speed control by weakening the magnetic flux is advantageous when the output power remains constant.

. Among the. disadvantages of the Ward-Leonard system are large Size, low efficiency due to the losses in the three auxiliary machines, and sluggishness in response. .

For a shunt machine we can construct a universal characteristic (Fig. 44). If we use an independent motor to drive the armature at a speed exceeding that for an ideal no-load condition. nnl , the armature current Will undergo a reversal, and the machine will operate as a generator into a d.c. line. If we apply a sufficiently large braking torque to the motor shaft, the motor will come to a stop. H the braking torque is supplied by, say, a rapidly falling load, the machine will change from the motor mode to the electric brake mode. This form of retarding the motor speed or of completely stopping the motor or reversing it by the application of power in the reverse direction so that the motor develops a torque which is opposite to the direction of rotation is called plugging. In plugging the armature current is

Iarm = (V + Earm)/(rarm + r) (13.12)

where r is the rheostat resistance that must be cut into the armature circuit in order to limit the current. If no additional resistance were inserted in the circuit at stopping by plugging at the rated voltage, the armature current would be heavy enough to cause an irrepairable damage to the commutator and the armature winding.

If a particular application requires that a motor stop quickly, dynamic braking is used. In dynamic braking, the rotating armature is disconnected from the supply line, and a resistor is connected across the armature terminals. With the shunt field energized, the machine acts as a generator, and a counter-torque is developed which rapidly slows the machine. The resistor is called a dynamic-braking resistor.