TYPES OF INDUSTRIAL PROCESS

There is a vast number of different manufacturing processes being carried out in industry today All processes can be grouped into three main categories in relation to the type of operations that take place within the process:

1. continuous production;

2. batch production;

3. discrete item production,

Every process has individual characteristics and requirements that must be considered when a control system is to be designed.

Continuous processes

A continuous process (Fig. ] .5(a)) takes in raw materials at the input and runs continuously, producing finished material or product at the output. The process may run for long periods of lime, typically minutes, hours or even weeks in certain cases.

The production of sheer steel (Fig. 1.5(b)) is an example of a continuous process. This involves large red-hot blocks of steel being fed through a series of rollers, which compress the blocks. This reduces the thickness of steel in stages, finally producing sheet steel at the end of the roller line (output). This process can take several minutes to complete, depending on the lengths of steel fed in.

As the rollers reduce the thickness of the steel plate, the speed of the sheet through the system increases to around 500m/minute (1600 ft/minute). Control must be exercised over each set of rollers to maintain a constant output sheet thickness. Accurate and rapid control of the first set of rollers is particularly important to allow compensation for input steel blocks of varying thickness.

Batch processes

A batch process uses a set quantity of source (input) materials and performs process operations on this material, producing a specific quantity of finished product (output) or product that will undergo further stages of processing. Fig. 1.6 shows a typical batch processing system.

Here chemicals are pumped into tanks 1 and 2 from reservoirs of polymer and alkali. The polymer is heated to 60°C and is then transferred to tank 3 where it is mixed with the alkali for a set period of time. The mixture now passes through other stages in the process as a batch, rather than as a continuous process. This includes passing through a filter into tank 4 as a complete batch of product .

Several different batch processes make up the complete cycle: measuring quantities of materials, heating, stirring and filtering, etc. Each activity requires some form of control to ensure the correct formation of each batch. For example, correct volumes of alkali and polymer, a alkali, etc. The type of control used at each stage depends on the individual process , but typically would be on/off discontinuous control for most of these tasks.

Discrete parts production

In this type of process an individual item undergoes various operations before being produced in a final form. Alternatively, several components may be combined or assembled within the process to emerge as an individual item or unit.

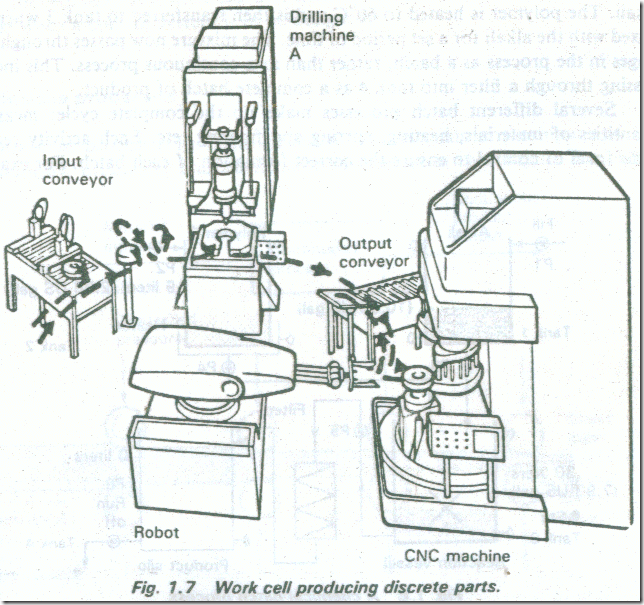

An example of discrete parts production is illustrated in Fig. J .7. Here metal blanks are loaded onto a drilling table by a robot arm, where they are securely clamped. The blanks are then drilled with a pattern of holes by different drill bits mounted in a rotating ‘selector’ head. The finished workpiece is then released from the table and placed on an adjacent conveyor belt by the robot arm, and so on.

This example involves several operating sequences: robot picks up blank and places on table; blank clamped to table; blank drilled with a preset pattern by drilling machine, etc. Most of these activities will be controlled on a binary on/off basis, including linking between each machine to pass information that the previous operation has finished, and the next may begin. This is commonly known as interlocking.