Merits and Demerits of Rheostatic Control Method

1. Speed changes with every change in load, because speed variations depend not only on controlling resistance but on load current also. This double dependence makes it impossible to keep the speed sensibly constant on rapidly changing loads.

2. A large amount of power is wasted in the controller resistance. Loss of power is directly proportional to the reduction in speed. Hence, efficiency is decreased.

3. Maximum power developed is diminished in the same ratio as speed.

4. It needs expensive arrangement for dissipation of heat produced in the controller resistance.

5. It gives speeds below the normal, not above it because armature voltage can be decreased (not increased) by the controller resistance.

This method is, therefore, employed when low speeds are required for a short period only and that too occasionally as in printing machines and for cranes and hoists where motor is continually started and stopped.

Advantages of Field Control Method

This method is economical, more efficient and convenient though it can give speeds above (not below) the normal speed. The only limitation of this method is that commutation becomes unsatisfactory, because the effect of armature reaction is greater on a weaker field.

It should, however, be noted that by combining the two methods, speeds above and below the normal may be obtained.

Series-parallel Control

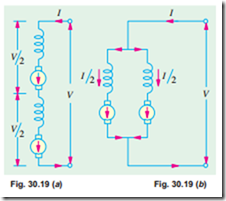

In this system of speed control, which is widely used in electric traction, two or more similar mechanically-coupled series motors are employed. At low speeds, the motors are joined in series Fig. 30.19 (a) and for high speeds, are joined in parallel Fig. 30.19 (b).

When in series, the two motors have the same V 2 current passing through them, although the voltage across each motor is V/2 i.e., half the supply voltage. When joined in parallel, voltage across each machines is V, though current drawn by each motor is I/2.

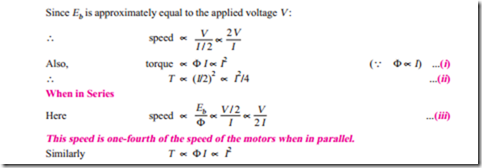

When in Parallel

Now speed µ Eb / f µ Eb / current (being series motors)

The torque is four times that produced by motors when in parallel.

This system of speed control is usually combined with the variable resistance method of control described in Art. 30.3 (2).

The two motors are started up in series with each other and with variable resistance which is cut out in sections to increase the speed. When all the variable series resistance is cut out, the motors are connected in parallel and at the same time, the series resistance is reinserted. The resistance is again reduced gradually till full speed is attained by the motors. The switching sequence is shown in Fig.30.20. As the variable series controller resistance is not continuously rated, it has to be cut out of the circuit fairly quickly although in the four running positions A, B,C and D, it may be left in circuit for any length of time.

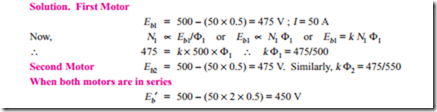

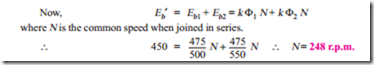

Example 30.44. Two series motors run at a speed of 500 r.p.m. and 550 r.p.m. respectively when taking 50 A at 500 V. The terminal resistance of each motor is 0.5 W. Calculate the speed of the combination when connected in series and coupled mechanically. The combination is taking 50 A on 500 V supply. (Electrical Machinery-I, Mysore Univ. 1985)

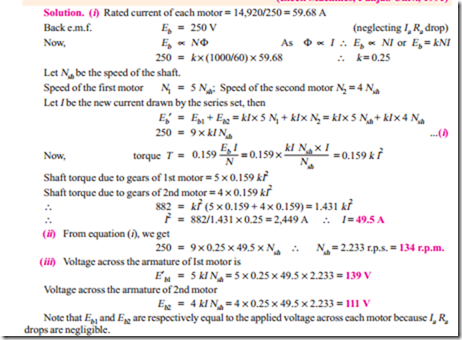

Example 30.45. Two similar 20 h.p. (14.92 kW), 250 V, 1000 r.p.m. series motors are connected in series with each other across a 250 V supply. The two motors drive the same shaft through a reduction gearing 5 : 1 and 4 : 1 respectively. If the total load torque on the shaft is 882 N-m, calculate (i) the current taken from the supply main (ii) the speed of the shaft and (iii) the voltage across each motor. Neglect all losses and assume the magnetic circuits to be unsaturated.

(Elect. Machines, Punjab Univ., 1991)

Related posts:

Incoming search terms:

- advantages and disadvantages of armature control

- merits and demerits of rheostatic control method

- advantages of armature control method

- disadvantage of field speed control in dc shunt motor

- Advantages of field control of dc motor

- merits of rheostatic control method

- advantages of speed control

- advantage of eletronic speed control of motors

- advantages and disadvantages of armature voltage control method

- advantages of speed control of dc shunt motor

- limitations of field control

- advantages and disadvantages of speed control of dc motor

- merit and demerit of armature control over field control

- disadvantages of field control method

- merits and demerits of field control over armature control

- merits demerits of sped control

- Advantages of speed control of dc motor

- rheostat advantages and disadvantages

- advantages and disadvantages of armature control method

- advantage of field control method

- advantage of field control over armature control

- explain speed advatages

- merits and demerits of various methods of speed control of a dc shunt motor

- advantage of armature control method

- describe various methid of speed controlof dc shuntmitor along with theur merits and de marits

- advantages of field control method

- advantage of armature control

- Advantages and disadvantages of field control

- aspect in speed merit and demerits

- advantage controling speed of dc motor

- advantages and dis advantages of armature control over flux control method of speed control

- merits of armature resistance and field speed control

- advantage and disadvantage of field control method

- advantages of flux control in dc motor

- advantages of field control of dc motors

- state the advantages and disadvantages of field control of dc motors

- speed control advantage

- advantage of speed control of DC motor

- merits of speed control of shunt motor

- merit and demerit of velodyne speed control system

- merits and demerits of motor speed control method

- advantages of speed control of dc motors

- disadvantages of armature control method

- what is the diadvantage of speed control shunt motor

- advantages and disadvantages of a velodyne speed control of a d c motor

- velodyne speed control system

- disadvantages of motor speed control

- advantages and disadvantages of field control of dc motors

- advantage and disadvantage of field control over armature control

- advantage of dc pmc controler