Iron Loss in Armature

Due to the rotation of the iron core of the armature in the magnetic flux of the field poles, there are some losses taking place continuously in the core and are known as Iron Losses or Core Losses. Iron losses consist of (i) Hysteresis loss and (ii) Eddy Current loss.

(i) Hysteresis Loss (Wh)

This loss is due to the reversal of magnetisation of the armature core. Every portion of the rotating core passes under N and S pole alternately, thereby attaining S and N polarity respectively. The core undergoes one complete cycle of magnetic reversal after passing under one pair of poles. If P is the number of poles and N, the armature speed in r.p.m., then frequency of magnetic reversals is f = PN/120.

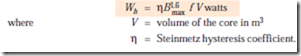

The loss depends upon the volume and grade of iron, maximum value of flux density Bmax and frequency of magnetic reversals. For normal flux densities (i.e. upto 1.5 Wb/m2), hysteresis loss is given by Steinmetz formula. According to this formula,

Good dynamo sheet steel = 502 J/m3, Silicon steel = 191 J/m2, Hard Cast steel = 7040 J/m3, Cast steel = 750 – 3000 J/m3 and Cast iron = 2700 – 4000 J/m3.

(ii) Eddy Current Loss (We)

When the armature core rotates, it also cuts the magnetic flux. Hence, an e.m.f. is induced in the body of the core according to the laws of electromagnetic induction. This e.m.f. though small, sets up large current in the body of the core due to its small resistance. This current is known as eddy current. The power loss due to the flow of this current is known as eddy current loss. This loss would be considerable if solid iron

core were used. In or- der to reduce this loss and the consequent heat- ing of the core to a small value, the core is built up of thin laminations, which are stacked and then riveted at right angles to the path of the eddy currents. These core laminations are in-

sulated from each other by a thin coating of var-

Fig. 26.62

nish. The effect of laminations is shown in Fig. 26.62. Due to the core body being one continuous solid iron piece [Fig. 26.62 (a)], the magnitude of eddy currents is large. As armature cross-sectional

area is large, its resistance is very small, hence eddy current loss is large. In Fig. 26.62 (b), the same core has been split up into thin circular discs insulated from each other. It is seen that now each current path, being of much less cross-section, has a very high resistance. Hence, magnitude of eddy currents is reduced considerably thereby drastically reducing eddy current loss.

It is found that eddy current loss We is given by the following relation :

It is seen from above that this loss varies directly as the square of the thickness of laminations, hence it should be kept as small as possible. Another point to note is that Wh µ f but We µ f 2. This fact makes it possible to separate the two losses experimentally if so desired.

As said earlier, these iron losses if allowed to take place unchecked not only reduce the efficiency of the generator but also raise the temperature of the core. As the output of the machines is limited, in most cases, by the temperature rise, these losses have to be kept as small as is economically possible.

Eddy current loss is reduced by using laminated core but hysteresis loss cannot be reduced this way. For reducing the hysteresis loss, those metals are chosen for the armature core which have a low hysteresis coefficient. Generally, special silicon steels such as stalloys are used which not only have a low hysteresis coefficient but which also possess high electrical resistivity.