Compound Motors

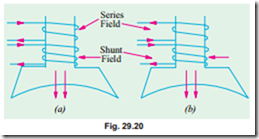

These motors have both series and shunt windings. If series excitation helps the shunt excitation i.e. series flux is in the same direction (Fig. 29.20); then the motor is said to be cummulatively com- pounded. If on the other hand, series field opposes the shunt field, then the motor is said to be differentially compounded.

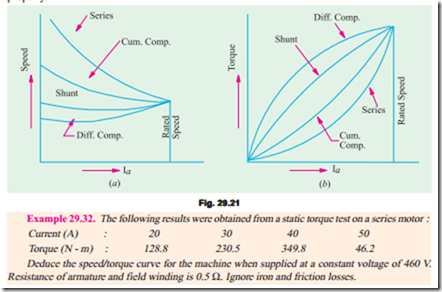

The characteristics of such motors lie in between those of shunt and series motors as shown in Fig. 29.21.

(a) Cumulative-compound Motors

Such machines are used where series characteristics are required and where, in addition, the load is likely to be removed totally such as in some types of coal cutting machines or for driving heavy machine tools which have to take sudden cuts quite often. Due to shunt windings, speed will not become excessively high but due to series windings, it will be able to take heavy loads. In conjunction with fly-wheel (functioning as load equalizer), it is employed where there are sudden temporary loads as in rolling mills. The fly-wheel supplies its stored kinetic energy when motor slows down due to sudden heavy load. And when due to the removal of load motor speeds up, it gathers up its kinetic energy.

Compound-wound motors have greatest application with loads that require high starting torques or pulsating loads (because such motors smooth out the energy demand required of a pulsating load). They are used to drive electric shovels, metal-stamping machines, reciprocating pumps, hoists and compressors etc.

(b) Differential-compound Motors

Since series field opposes the shunt field, the flux is decreased as load is applied to the motor. This results in the motor speed remaining almost constant or even increasing with increase in load (because, N µ Eb/(F). Due to this reason, there is a decrease in the rate at which the motor torque increases with load. Such motors are not in common use. But because they can be designed to give an accurately constant speed under all conditions, they find limited application for experimental and research work.

One of the biggest drawback of such a motor is that due to weakening of flux with increases in load, there is a tendency towards speed instability and motor running away unless designed properly.

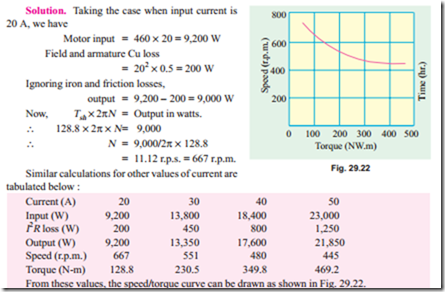

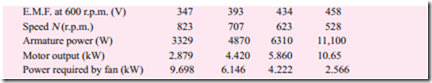

Example 29.33. A fan which requires 8 h.p. (5.968 kW) at 700 r.p.m. is coupled directly to a d.c. series motor. Calculate the input to the motor when the supply voltage is 500 V, assuming that power required for fan varies as the cube of the speed. For the purpose of obtaining the magnetisation characteristics, the motor was running as a self-excited generator at 600 r.p.m. and the relationship between the terminal voltage and the load current was found to be as follows :

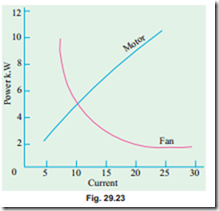

In Fig. 29.23 (i) the motor output in kW and (ii) power required by fan in kW against input currentis plotted. Since motor output equals the input to fan, hence the intersection point of these curves gives the value of motor input current under the given conditions.

Input current corresponding to intersection point = 12 A

Motor input = 500 ´ 12 = 6,000 W

Performance Curves

(a) Shunt Motor

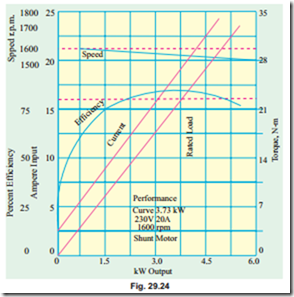

In Fig. 29.24 the four essential characteristics 8 of a shunt motor are shown i.e. torque, current speed and efficiency, each plotted as a function of motor 6 output power. These are known as the performance curves of a motor. 4

It is seen that shunt motor has a definite no-load speed. Hence, it does not ‘run away’ when 2 load is suddenly thrown off provided the field cir Fan cuit remains closed. The drop in speed from no- load to full-load is small, hence this motor is usu- ally referred to as constant speed motor. The speed for any load within the operating range of the motor can be readily obtained by

ally of the same shape for all electric motors and generators. The shape of efficiency curve and the point of maximum efficiency can be varied considerably by the de- signer, though it is advantageous to have an efficiency curve which is farily flat, so that there is little change in efficiency between load and 25% overload and to have the maximum efficiency as near to the full load as possible.

It will be seen from the curves, that a certain value of current is required even when output is zero. The motor inputAs compared to other motors, a shunt motor is said to have a lower starting torque. But this should not be taken of mean that a shunt motor is incapable of starting a heavy load. Actually, it means that series and compound motors are capable of starting heavy loads with less excess of current inputs over normal values than the shunt motors and that consequently the depreciation on the motor will be relatively less. For example, if twice full load torque is required at start, then shunt motor draws twice the full-load current (Ta µ Ia or Ia µ Ta ) whereas series motor draws only approximately one and a half times the full load current (Ta µ Ia or Ia µ Ta ).

The shunt motor is widely used with loads that require essentially constant speed but where high starting torques are not needed. Such loads include centrifugal pumps, fans, winding reels conveyors and machine tools etc.

(b) Series Motor

The typical performance curves for a series motor are shown in Fig. 29.25.

It will be seen that drop in speed with increased load is much more prominent in series motor than in a shunt motor. Hence, a series motor is not suitable for applications requiring a substantially constant speed.

For a given current input, the starting torque developed by a series motor is greater than that developed by a shunt motor. Hence, series motors are used where huge starting torques are necessary i.e. for street cars, cranes, hoists and for electric-railway operation. In addition to the huge starting torque, there is another unique characteristic of series motors which makes them especially desirable for traction work i.e. when a load comes on a series motor, it responds by decreasing its speed (and hence, Eb) and supplies the increased torque with a small increase in current. On the other hand a shunt motor under the same conditions would hold its speed nearly constant and would supply the required increased torque with a large increase of input current. Suppose that instead of a series motor, a shunt motor is used to drive a street car. When the car ascends a grade, the shunt motor maintains the speed for the car at approximately the same value it had on the level ground, but the motor tends to take an excessive current. A series motor, however, automatically slows down on such a grade because of increased current demand, and so it develops more torque at reduced speed. The drop in speed permits the motor to develop a large torque with but a moderate increase of power. Hence, under the same load conditions, rating of the series motor would be less than for a shunt motor.

Related posts:

Incoming search terms:

- efficiancy of cumulative and differential compound motors

- motor used in reciprocating pump?

- cumulative compound motor

- motor used in reciprocating pump

- pic of a compound dc motor

- type of dc pump series or compound dc pump

- efficiency of cumulative and differential compound motors

- which motor used in reciprocating pump

- compound motor application

- Reciprocating pump which motor is used

- which motor is used in reciprocating pump

- which motor is used in recipro

- uses of cummulatively compounded motor

- use of cumulative compound motor

- which motor is used in resiprocating pumb

- tools are used to make Dc compound motor

- compound motor

- motor used in reciprocal pump

- four uses of cummulatively compounded

- for crane hoist cumulative compound motor is used

- differential compound motor under over load condition

- dc motor used in reciprocating pump

- dc compound motor used in reciprocating pump

- Which type of DC motor is suitable for uses in high starting torque and load is likely to be removed totally?